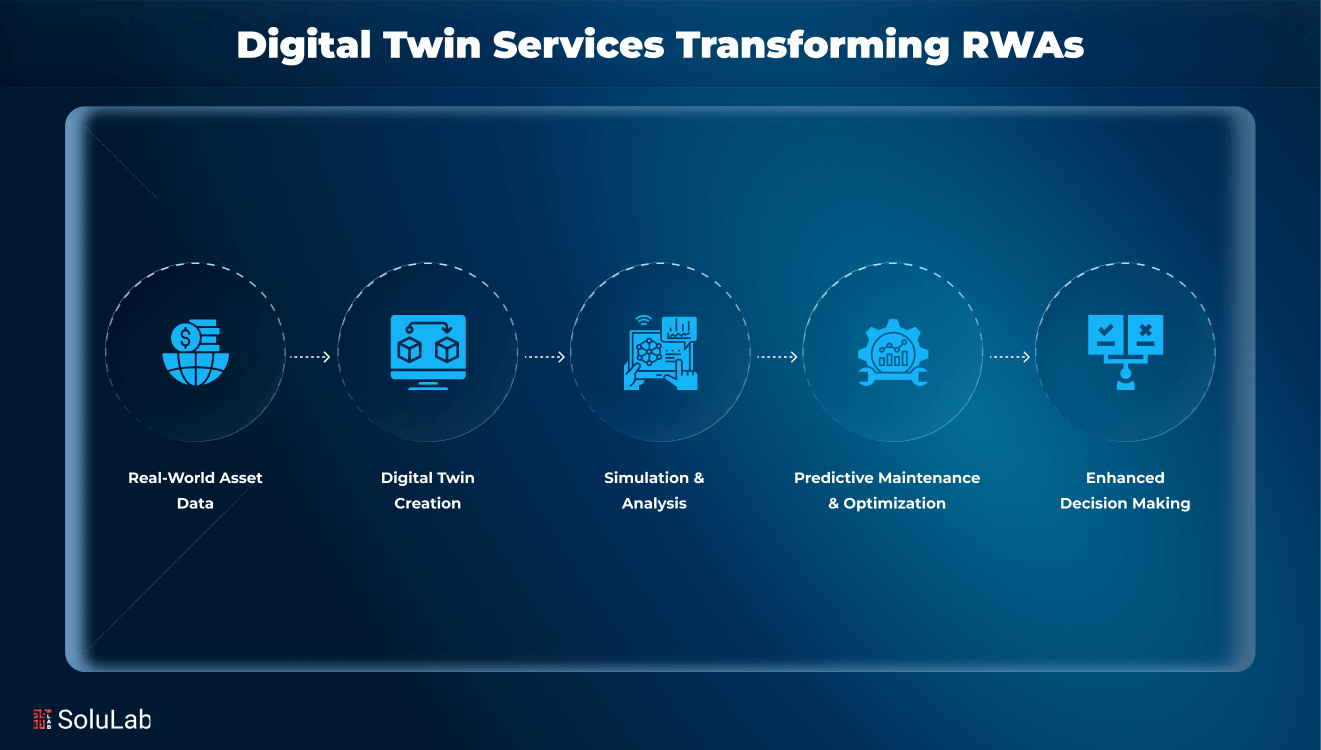

Imagine being able to test, predict, and optimize your physical assets—before making a single real-world change. That’s the power of Digital Twin technology, and in 2026, it’s becoming smarter, faster, and more accessible than ever. By creating a virtual replica of real-world assets, businesses can simulate performance, reduce risks, and unlock new levels of efficiency.

From smart factories and energy grids to healthcare systems and urban planning, Digital Twin services are set to revolutionize how industries manage, monitor, and grow their assets. In this blog, we’ll explore how this cutting-edge technology is shaping the future—and why now is the time to invest in it.

Understanding Digital Twin Technology in a Connected World

A digital twin is a real-time virtual model of a physical object, process, or system. It continuously mirrors the state and behavior of its real-world counterpart using live sensor data and smart analytics. Digital twin software allows users to simulate, monitor, and optimize physical assets without touching the real system.

Simulations show hypothetical scenarios based on static inputs and assumptions. They cannot change unless updated manually by the designer. Digital twins are dynamic, constantly updated with real-time data from physical systems, enabling live decision-making and predictive insights.

How Digital Twins Operate with Real-Time Data?

Digital twin technology works by continuously syncing with physical assets using live sensor data. IoT devices track key metrics like temperature, vibration, pressure, and energy levels. This real-time data feeds into a centralized platform that mirrors the asset’s condition virtually.

As updates happen instantly, engineers and operators can view the twin across mobile, desktop, or immersive devices like AR and VR. These visual models allow teams to simulate operations, detect performance drops, and interact with the system as if it were physical.

Key capabilities include:

- Live monitoring of physical changes through dynamic 3D models and interactive dashboards.

- Instant alerts and updates, ensuring timely decisions and smoother operations.

This real-time sync transforms static systems into dynamic, visual environments that evolve with the asset.

Role of IoT and AI in Enabling Digital Twins

The backbone of any digital twin is data. IoT plays the role of the sensory system, collecting real-time signals from the physical world. These signals come from sensors attached to machines, buildings, or infrastructure.

AI functions as the brain, interpreting and analyzing this flood of data. Machine learning models study historical patterns and current performance to forecast potential failures or suggest improvements. Together, IoT and AI form a self-updating, smart digital twin that continuously learns and improves. Hence, this integration brings innovative digital twin services into the real world.

Combined benefits of IoT and AI:

- IoT captures reality; AI adds intelligence through learning, prediction, and automation.

- The system becomes adaptive, reacting to real-time changes and supporting autonomous decision-making.

This integration of sensors and intelligence enables proactive maintenance, smarter workflows, and reduced downtime, without human intervention.

Read Also: Why Is Real-World Asset Tokenization Gaining Global Popularity?

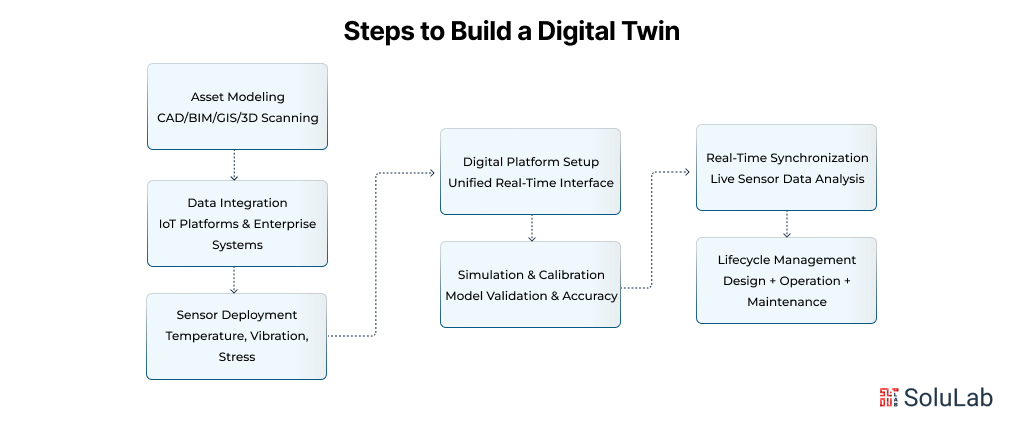

Steps to Build a Digital Twin

Building a Digital Twin isn’t just about creating a virtual replica—it’s about integrating real-time data, analytics, and simulations to mirror and optimize physical assets. Here’s how the process works:

- Asset Modeling: Create a 3D model of the physical asset using CAD, BIM, GIS, or 3D scanning tools.

- Data Integration: Connect the model to real-world data sources like IoT platforms, enterprise systems, and inspection records.

- Sensor Deployment: Install sensors on the physical asset to collect live data such as temperature, vibration, and stress levels.

- Digital Platform Setup: Use a digital twin platform to combine the model and data streams in one real-time interface.

- Simulation and Calibration: Run initial simulations to validate the model’s accuracy and calibrate it to match real-world performance.

- Real-Time Synchronization: Continuously update the twin with live sensor inputs for real-time analysis and decision-making.

- Lifecycle Management: Maintain the digital twin across all phases, design, operation, maintenance, and eventual decommissioning.

Tools and data used during the process of digital twin manufacturing

- Sensors and IoT Devices: Capture real-time metrics from the physical asset for continuous updates and monitoring.

- Cloud Platforms: Store, process, and secure large volumes of live and historical data from connected systems.

- 3D Simulation Engines: Power real-time visualizations and advanced simulations for performance, stress, and failure prediction.

- Modeling Software: Use CAD, BIM, or GIS tools to design the initial digital structure of the asset.

- Analytics and AI Tools: Analyze patterns, predict issues, and enhance decision-making using machine learning and advanced algorithms.

- Enterprise Systems: Integrate operational data like maintenance history and usage logs for complete asset visibility.

Types of Digital Twins and Their Use Cases

Digital twins come in different types, each built for a specific level of detail and complexity. This table shows how they differ and where they’re most commonly used in real-world industries.

| Type | Description | Common Use Cases |

| Component Twin | Digital model of a single part | Motors, pumps, pipes |

| Asset Twin | Combines multiple components | Equipment systems, HVAC units |

| System Twin | Models interactions between multiple assets | Power grids, manufacturing lines |

| Process Twin | Replicates full operational workflows | Refineries, production plants |

| Structural Twin | High-fidelity model with real-time physics simulations | Offshore platforms, bridges |

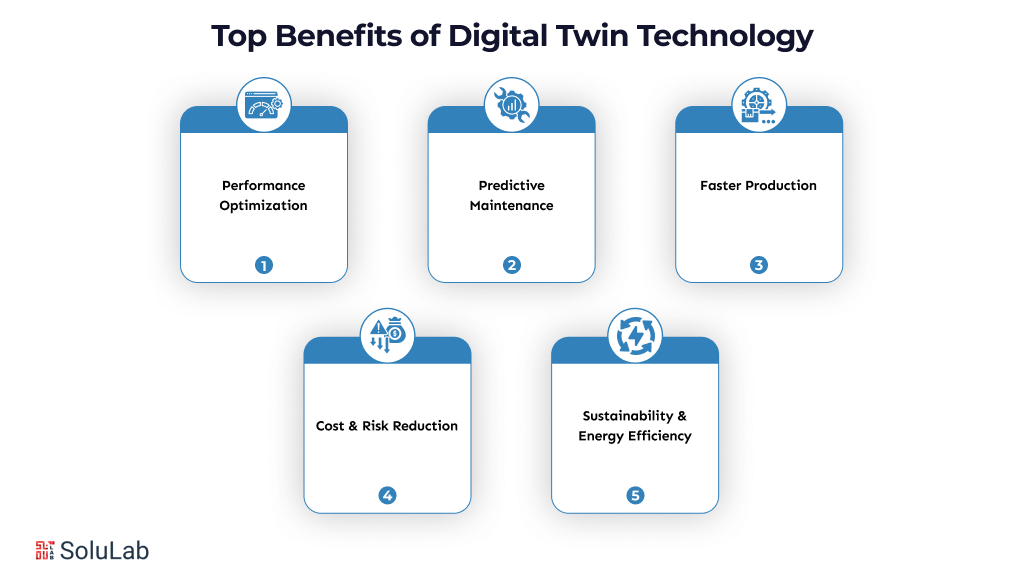

Top Benefits of Digital Twin Technology

Digital Twin technology bridges the physical and digital worlds, offering businesses a smarter way to manage assets, reduce risks, and maximize performance. Here are the key benefits:

-

Performance Optimization

Digital twins monitor asset health and performance continuously. They help operators fine-tune processes and eliminate inefficiencies in real time. This leads to reduced downtime and improved productivity across all stages of operations.

-

Predictive Maintenance

Sensors detect early signs of wear or failure, alerting engineers before breakdowns occur. Remote access to data means fewer site visits and safer monitoring of hazardous assets like reactors or offshore rigs. Operators can make timely repairs based on real-time stress points identified by the digital twin.

-

Faster Production

Digital twin software simulates different design options quickly, reducing prototyping costs and development time. By testing virtually, teams avoid risks and confidently choose the best solution for real-world deployment.

-

Cost & Risk Reduction

By simulating scenarios virtually, companies can test strategies, production changes, or design modifications without expensive real-world experiments—saving both time and resources.

-

Sustainability & Energy Efficiency

Organizations can use Digital Twins to track energy consumption and carbon emissions, optimize resource usage, and align with green initiatives.

Industries Adopting Digital Twin Solutions Rapidly

Digital Twin technology is no longer confined to research labs or futuristic concepts—it’s already transforming multiple industries by enabling smarter decisions, reducing risks, and improving efficiency. Here are some sectors leading the way:

-

Construction

Construction teams use digital twins for project planning, site monitoring, and design validation. Facility managers monitor air quality, occupancy, and energy use in smart buildings with live digital twin dashboards. Architects use twins to simulate light, airflow, and space efficiency before construction begins.

-

Manufacturing and Industrial Use

Manufacturers deploy digital twins across assembly lines to track equipment health and predict failures. They analyze machine performance data to optimize workflows, reduce waste, and lower maintenance costs.

-

Energy, Automotive, and Healthcare

Energy companies use structural digital twins for wind turbines, reactors, and pipelines under extreme conditions. Automotive firms model entire vehicle systems to improve designs, detect problems early, and guide repairs. Healthcare providers simulate organs and treatments, improving patient outcomes and optimizing hospital resources.

What’s Next for Digital Twins?

Digital Twin technology is moving far beyond basic asset monitoring—it’s evolving into a cornerstone of digital transformation. With advancements in artificial intelligence, IoT, cloud computing, and 5G connectivity, the future of Digital Twins looks even more powerful and widespread.

1. Growth Potential In Smart Cities And Beyond

Urban areas generally use digital twin services to manage traffic lights, water systems, and power grids. This is mainly to identify any problem in no time. For sustainable growth in high-density areas requires careful monitoring is required. Hence, urban planners simulate zoning, pollution, and population growth to make city life better.

2. Future-Ready Use Of Immersive 3D And Real-Time Models

As technology grows, real-time 3D and AR/VR will provide more user-friendly digital twin solutions. These 3D devices are mainly used for interactive, immersive, and intuitive purposes. In upcoming years, simulation, live data, and AI will be integrated into one and enhance decision-making.

Conclusion

Digital Twin technology is no longer a futuristic concept—it’s a practical solution already reshaping industries in 2026. From manufacturing and healthcare to smart cities and energy, businesses are unlocking new possibilities by creating virtual replicas of their assets. The result? Smarter operations, reduced risks, cost savings, and sustainable growth.

SoluLab, a top AI-powered digital twin service provider, helps businesses run simulations. Whether you want to optimize operations, improve asset performance, or explore new revenue streams, our team ensures end-to-end support—from strategy and development to deployment and scaling.

If you want to build an efficient digital twin for your business, contact us today!

FAQs

1. What exactly is a digital twin?

A digital twin is like a live virtual copy of a machine or building. It shows how things work in real life using real-time data from sensors and software.

2. How can a digital twin help my business?

It helps you spot problems before they happen, make smarter decisions, and improve performance, all without touching your actual equipment or facility. It’s like having X-ray vision.

3. Is digital twin technology expensive to set up?

It depends on your project size. Small systems cost less, while complex setups need more tools. But the savings in downtime and efficiency often make it totally worth it.

4. Can digital twins work for old machines?

Yes! Older machines can be retrofitted with sensors. Once connected, they can join your digital twin system and start sharing useful performance and maintenance data instantly.

5. Who should I contact for digital twin development?

You can reach out to SoluLab. Their team builds smart, custom digital twin solutions that match your business goals and help bring your assets to life, virtually!