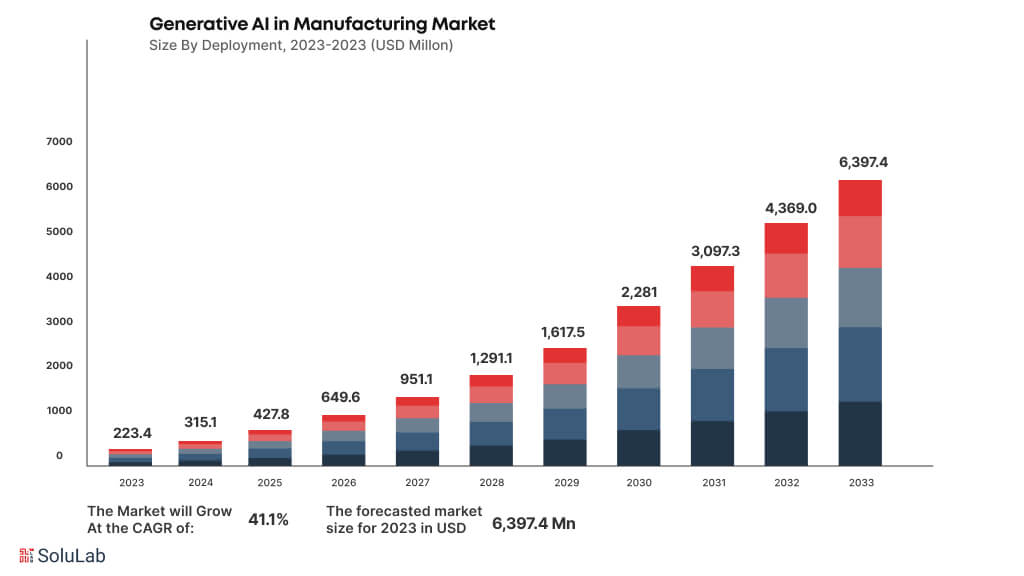

Artificial intelligence is becoming a major driver behind the significant changes within various industries in the quickly changing field of technology. The industrial sector is one of the most notable beneficiaries of AI, leveraging its achievements and potential to improve its operations and create new avenues for growth.

From streamlining production processes to enhancing decision-making, AI has become an indispensable tool for manufacturers seeking to stay competitive in an increasingly complex global market.

Generative AI analyzes complicated data to improve operational strategies at the organizational and factory floor levels, challenging the legacy systems and conventional management practices that underpin traditional manufacturing. Hence, generative AI gives manufacturers the tools they need to solve problems with data quality and fully utilize AI in their process.

As the manufacturing landscape evolves, product design optimization stands out as a critical aspect, and AI plays a pivotal role in this endeavor. Below, we explore the multifaceted facets of AI in manufacturing design optimization, shedding light on Generative AI use cases and the inherent benefits.

Where Gen AI Matters?

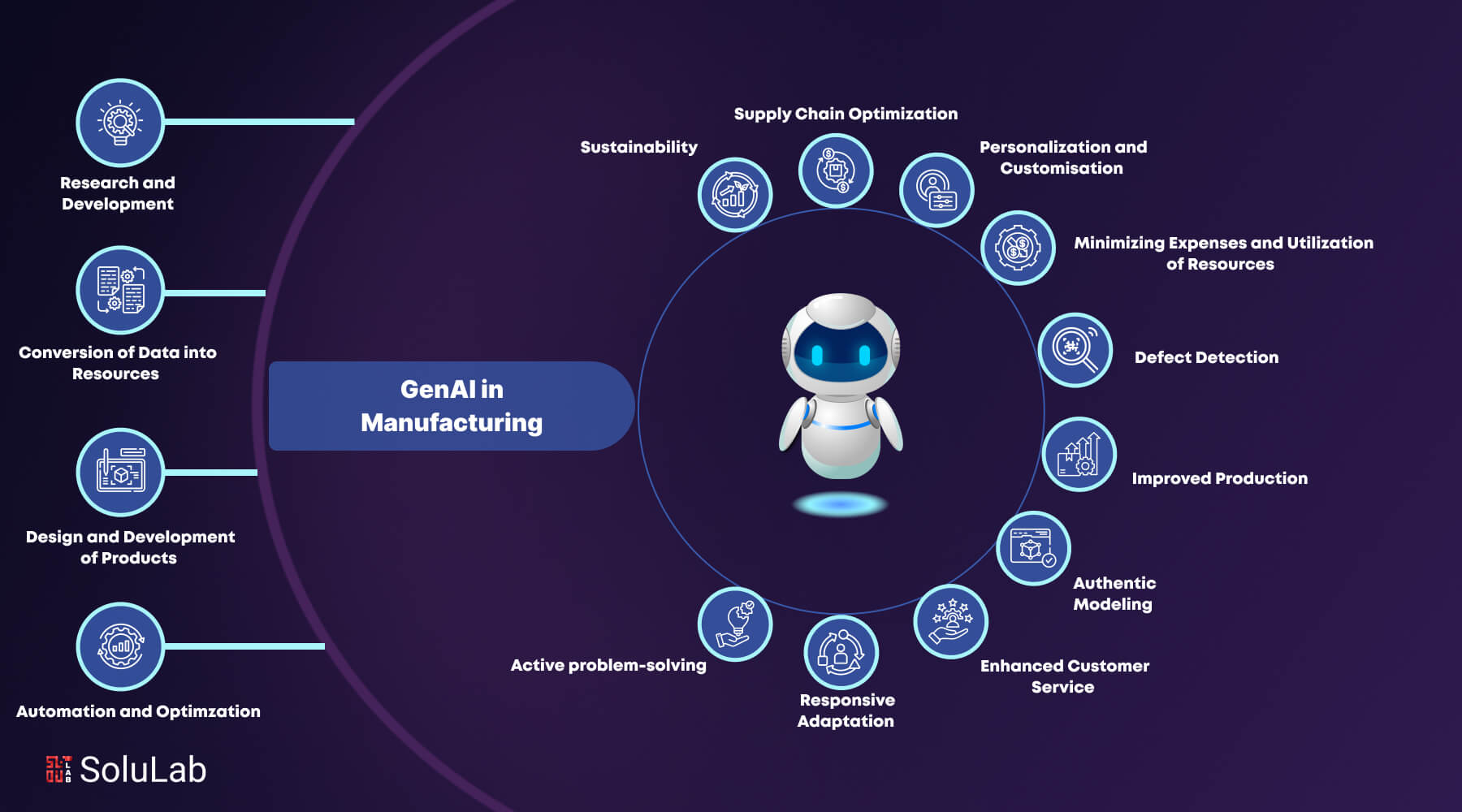

There are a lot of potential uses of generative AI in manufacturing, and an image of an AI-driven workplace that offers advantages throughout the plan-make-deliver value stream is starting to take shape.

1. With Gen AI, demand estimates could improve planning procedures by integrating qualitative analysis from customer experiences and cross-functional insights. It can then suggest the next best production schedules that would help minimize supply chain disruptions. It can also give you real-time recommendations on inventory reduction or insight into the state of the inventory.

2. Generative AI enables the detection of failures and minimizes errors through root-cause analysis, hence increasing industrial productivity using Gen AI. The systems also create simple, dynamic job instructions and improve the operator stations through AI-assisted troubleshooting and operational manuals.

3. Additionally, the automation of document production, confirmation completions before transit, and customer interaction via AI chatbots services for the tracking of orders and creation will be enabled by generative AI, this ensures timely and complete delivery of the products to the consumers.

How Can Gen AI be Incorporated Into Workflow?

Effective integration is the key to realizing the possibility of generative AI in corporate processes, which can yield substantial gains in productivity, efficiency, and cost reduction. To successfully integrate Gen AI into manufacturing workflows, enterprises need to exercise greater caution and adhere to a structured approach.

For successful integration of Gen AI in the production procedures, it is important to assess the current workflow and processes by paying close attention to the major areas with the help of detailed analysis for finding efficiencies, obstacles, and overall issues. Also, prioritize manufacturing operations and tasks that stand to gain most of GenAI integration for predetermining certain use cases.

Continuous monitoring and keep-ups with customer feedback put together a more reliable form of Generative AI that not alone measures performance but evaluates results too. The use of cross-functional programs has advanced awareness and the global acceptance of GenAI to foster cooperation within domains and experts.

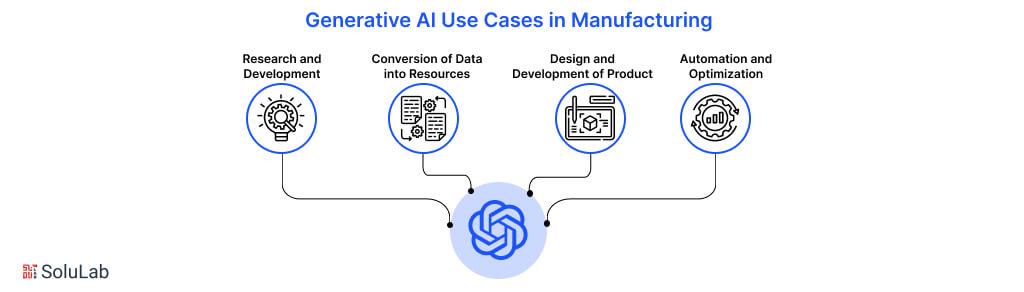

Use Cases of Gen AI in Manufacturing

1. Research and Development

Generative AI acts as a strong tool with the support of data-driven R&D in manufacturing, offering state-of-the-art techniques for spotting new market trends, assessing product utilization, and a better understanding of what the customer exactly wants. This descriptive analysis provides insight into the previous data along with possible future trends by painting a compact picture of key features of the datasheet.

2. Conversion of Data into Resources

Manufacturing has only been improved with the integration of generative AI with the help of optimization and data analysis product design guidance. A blend of continuous learning, predictive modeling, and data analysis is made to achieve this, The initial step is to gather the data from all kinds of sources. Once this data is clean and processed, it is normalized and any missing value is handled. This data is prepared for analysis.

3. Design and Development of Products

Manufacturing product development and design are being redefined by generative AI. Through the successive iterations, it picks up knowledge and learns to create a large number of design variants based on those factors. This approach has a great advantage in that it would result in more innovative and resource-efficient designs, really speed up the process of designing, and mostly better performing-resource-efficient-stronger structurally products.

4. Automation and Optimzation

Data-driven insights and predictive skills of generative AI have brought a major change in the industry with automation and optimization. It starts with gathering a variety of data from machine sensors and the Internet of Things (IoT) devices. The data is important for understanding many facets of the manufacturing process, including the soda ash manufacturing process. Another important use of this is in the computation of overall equipment effectiveness (OEE), which indicates the effectiveness of the production.

How is AI Reshaping the Manufacturing Industry?

In the ever-evolving dynamics of manufacturing, staying ahead requires a constant pursuit of efficiency. Enter Artificial Intelligence (AI), a transformative force amending production processes and propelling the industry into the future. Here are the points to explain the pivotal role of AI in enhancing production efficiency and explore real-world examples showcasing its profound impact.

-

Reducing Downtime Through Predictive Maintenance

One of the significant contributions of gen AI in the manufacturing industry is predictive maintenance. By harnessing machine learning algorithms, manufacturers can predict when equipment is likely to fail, allowing for proactive maintenance. This not only reduces unplanned downtime but also extends the lifespan of machinery, optimizing resource utilization.

Example: A leading automotive manufacturer implemented AI-driven predictive maintenance, resulting in a 20% reduction in downtime and a 15% increase in overall equipment effectiveness.

-

Optimizing Resource Utilization with Smart Automation

AI-driven automation goes beyond repetitive tasks, incorporating machine learning to adapt and improve over time. This ensures that resources are utilized optimally, from raw materials to energy consumption. Smart automation, guided by AI, leads to streamlined production processes and significant cost savings.

Example: A textile factory implemented AI-driven automation to monitor and adjust machine settings in real time. This not only reduced material wastage by 25% but also led to a 30% decrease in energy consumption.

-

A Creative Force in Design and Production

Generative AI is making waves in manufacturing by offering innovative solutions through creative problem-solving. In product design, it aids engineers in generating multiple design iterations and optimizing for efficiency, cost, and performance. This iterative process results in groundbreaking designs that may not be apparent through traditional methods.

Example: An aerospace company utilized generative AI to design aircraft components, leading to a 15% reduction in weight without compromising structural integrity. This not only improved fuel efficiency but also reduced manufacturing costs.

Top 10 Benefits of Gen AI in Manufacturing

Here are the top 10 benefits of implementing generative AI in manufacturing procedures:

-

Sustainability

Generative AI is so important for low or zero environmental impact, especially for sustainable industrial process realization. It assists businesses with environmentally friendly practice adoptions that largely reduce carbon emissions, hence benefiting the environment. It contributes by optimizing manufacturing processes, materials, and energy utilization toward sustainability. Their algorithms find ways of minimizing waste and using fewer resources, ending up with production methods that are more environmentally friendly.

-

Supply Chain Optimization

The application of generative AI in supply chain optimization stems from the ability of the former to interpret and assess large-scale data. By using advanced algorithms, it predicts demand trends, which enables the business to adjust its production plans and level of stock. In addition, generative AI optimizes supply chain logistics through route, time, and mode-of-transport optimization. This ensures that goods reach the clients faster due to reduced lead times and transportation costs.

Check Out Our Case Study: GenAI in Supply Chain Management

-

Personalization and Customisation

With generative AI, manufacturers can now better meet the peculiar needs and tastes of every client, greatly enhancing customer satisfaction and loyalty. Today, generative AI can be found in some different business industries with great success stories. It can change items to suit the particular needs of the customers by changing their features, color, size, or shape. This level of personalization exceeds that attainable from conventional methods of manufacturing, where the ability to fulfill individual tastes is normally constrained by economies of scale.

-

Minimizing Expenses and Utilization of Resources

Technology application will result in sustainable and economical production owing to a reduction in material waste and energy use. Generative AI is eager in data and trend analysis, hence will reduce material waste. AI algorithms, in the case of 3D printing, for example, optimize layer placement so that it decreases material usage without affecting structural integrity. This saves money from material costs by a considerable margin.

-

Defect Detection

Manufacturing relies a lot on quality control, and generative AI is at the helm to change this important aspect. Real-time defect identification is where it does exceptionally well, a feature that greatly enhances customer satisfaction and product quality. It flags products quickly with its constant monitoring of sensor data, product photos, and other parameters of quality using sophisticated algorithms.

-

Improved Production

With generative AI, companies can optimize workflows by automating complex operations and increasing productivity through better resource usage. For example, in manufacturing, AI algorithms can create production schedules that are optimized for maximum efficiency and minimal waste. Generative AI also has the potential to greatly enhance the productivity of customer support professionals in contact centers by providing them with ticket summaries, response suggestions, and tone recommendations.

-

Authentic Modeling

Generative AI makes it possible to simulate realistic environments for training, entertainment, and research. For example, AI-powered simulators can effectively simulate driving conditions within the automobile industry, allowing the safe and efficient testing of autonomous vehicles.

Read Blog: The Future of Generative AI in Automotive Industry

-

Enhanced Customer Service

Generative AI integration can answer with richer and deeper levels of sophistication due to the advanced underlying models that raise the quality of consumer interactions. The generative AI-driven operations can also serve as agents in customer service. They apply NLP to snoop on the agent-customer conversations and fetch relevant information to enhance the interaction.

-

Responsive Adaptation

These generative AI systems can learn continuously and make improvements based on user feedback and new data. This feature enables outputs that are closer to user preferences and goals, improving over time. For example, generative AI models in personalized education can dynamically revise learning materials and procedures in light of the needs, preferences, and learning styles of every individual student to enhance the effectiveness of the educational experience.

-

Active problem-solving

With generative AI-powered tools, it is now possible to provide real-time monitoring and risk analysis of industrial operations. It ensures that any problem is sorted out promptly and output and efficiency would be maximized in line with that. They are capable of detecting events at the time they happen, and as such, they can present insightful analysis and recommendations to help engineers and operators decide much faster on a solution before it gets worse.

How Can Generative AI Assist With Competitive Advantage?

Many advantages of AI in manufacturing are already noted and aware of, while the competitive advantage is quite overlooked irrespective of the growth and development it brings to businesses and the production industry. Large generative AI models are already generating original texts, graphics, and even code which can be fine-tuned with domain-specific data for creating marketing collateral, presenting new designs of products, and optimizing manufacturing processes.

1. Concept: Generative AI in manufacturing can be used for ideating concepts that are related to the designs and production of new products. A model can be trained on recent market trends and designs for past success thereby outputting a variety of original ideas that could appeal to buyers. These ideas can be confirmed for their viability by creating rapid prototypes through 3D printing or another manufacturing technique.

2. Participatory: Now, you can use AI to generate engaging marketing collateral illustrating your manufacturing capability. Take existing marketing collateral and consumer data to train a model that will allow you to create customized product videos, social media posts, or sales pitches for specific clients or market segments. This will help differentiate you in an increasingly crowded marketplace and deepen relationships with your clients.

3. Optimization: Other places where generative AI is used include optimizing workflows in manufacturing. You train a model on sensor data from production lines to look for ways to minimize downtime, cut waste, and make further gains in efficiency. It can suggest other temperatures, pressures, and speeds that work better. As it learns over time from the data, this model may become a very valuable tool for continuous improvement.

How is SoluLab Building The Future With Gen AI?

The aim of generative AI in manufacturing is not simply to increase efficiencies but to completely change the production process. Using advanced AI technologies, manufacturers can now innovate optimize, and interact with customers in ways previously unimaginable.

You will be able to use generative AI at your site in collaboration with SoluLab. Our experience in Generative AI development helps ensure that all spheres are growing and simplified, making your establishment competitive in any line of endeavor. Let us create a manufacturing capability revolution and achieve excellence together in your sector.

The benefits of incorporating Generative AI for manufacturing are multifaceted. Firstly, it enhances efficiency by optimizing production workflows, minimizing downtime, and streamlining resource allocation. SoluLab’s expertise in AI applications in manufacturing ensures a seamless integration that not only automates routine tasks but also adapts to evolving production

FAQs

1. What is Generative AI and how is it used in manufacturing?

A kind of generative AI that is highly focused on generative creative and new solutions much different than the existing data. For manufacturing, it can enhance productivity, speed up processes, provide better designs, and enable predictive assistance.

2. How is generative AI useful in improving product designs?

Generative AI can easily facilitate product designs with rapid creation and evaluation of various design options that are based on specific parameters, which not only results in creative designs but also provides users with exceptional efficiency.

3. What is the major challenge in impletion of Generative AI in manufacturing?

There are several challenges faced during the implementation of Generative AI in manufacturing but data quality and integration issues come out as the major ones. High data quality is pivotal for effective AI performance and integration with existing systems is difficult.

4. How can manufacturers begin with Generative AI?

One should start with the identification of specific areas in which generative AI will add value like designs, supply chains, and machines. Beginning with small pilot projects can help in gaining experience before implementation.

5. How can SoluLab assist in implementing Generative AI?

At SoluLab, we specialize in tailored Gen AI solutions for your needs and preferences. If you are looking to optimize production or implement predictive maintenance, our experts are ready to help you navigate the complexities.