Artificial intelligence is transforming the manufacturing business with its transformational potential. Major manufacturers are utilizing AI to improve efficiency, accuracy, and productivity across several operations.

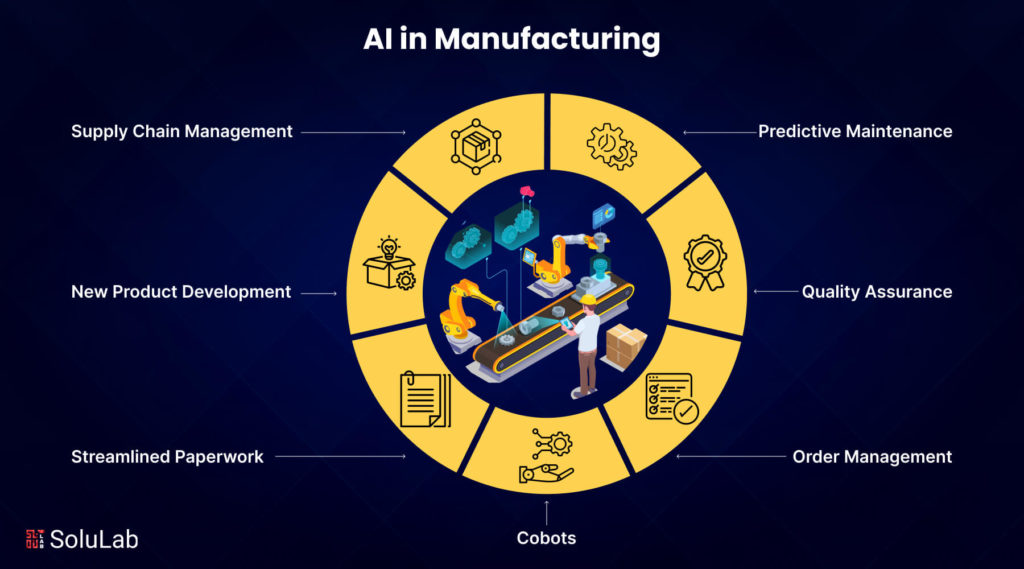

AI applications in manufacturing include a wide range of use cases, including predictive maintenance, quality control, supply chain optimization, and demand forecasting, providing a disruptive approach to old operations. For manufacturers, adopting AI is now a strategic move toward upgrading processes and keeping ahead in a competitive world.

According to a Deloitte report, manufacturing is the leading industry in terms of data creation. This suggests that a large amount of data is created within the manufacturing sector, demonstrating the industry’s major effect on the data environment. Manufacturers must use AI to examine the massive amounts of data created in the field.

According to a recent VentureBeat poll, 26% of firms are actively using generative AI to better their decision-making processes. Furthermore, 66% of manufacturers who incorporate AI into their everyday operations indicate a rising reliance on this revolutionary technology, indicating an increasing trend of AI use in the manufacturing industry.

In this blog, we will look at numerous use cases and examples that demonstrate how the combination AI applications in manufacturing enhances efficiency and ushers in a new era of smart manufacturing. We will also look at the influence of AI applications in manufacturing and how it enables firms to grow.

The Effect of Artificial Intelligence in Manufacturing

AI manufacturing is essential for increasing output, effectiveness, and decision-making in the manufacturing sector. AI application in manufacturing includes AI-driven predictive maintenance optimizes maintenance plans and reduces downtime by evaluating equipment data to foresee potential problems.

Machine learning algorithms streamline logistics, monitor inventory, and anticipate demand, all of which increase the efficiency of supply chain management. AI-powered robotics makes assembly line automation possible, improving speed and accuracy while adjusting to shifting production needs.

AI-powered quality control systems detect errors more precisely, ensuring consistency in the finished product. In order to optimize efficiency and minimize waste, it is also utilized in smart manufacturing to monitor operations in real time and make quick modifications.

According to PwC research, a subset of artificial intelligence called reinforcement learning can optimize the manufacture of electrical devices by dynamically modifying machine settings in smart manufacturing. By means of ongoing learning and adjustment, the system optimizes production, reduces errors, and improves resource allocation, resulting in increased profitability and a competitive advantage.

All things considered, AI transforms the manufacturing sector by promoting creativity, reducing costs, and enhancing overall operational effectiveness. Let’s explore some common applications of AI for manufacturing using real-life examples to have a better understanding of the technology’s significance.

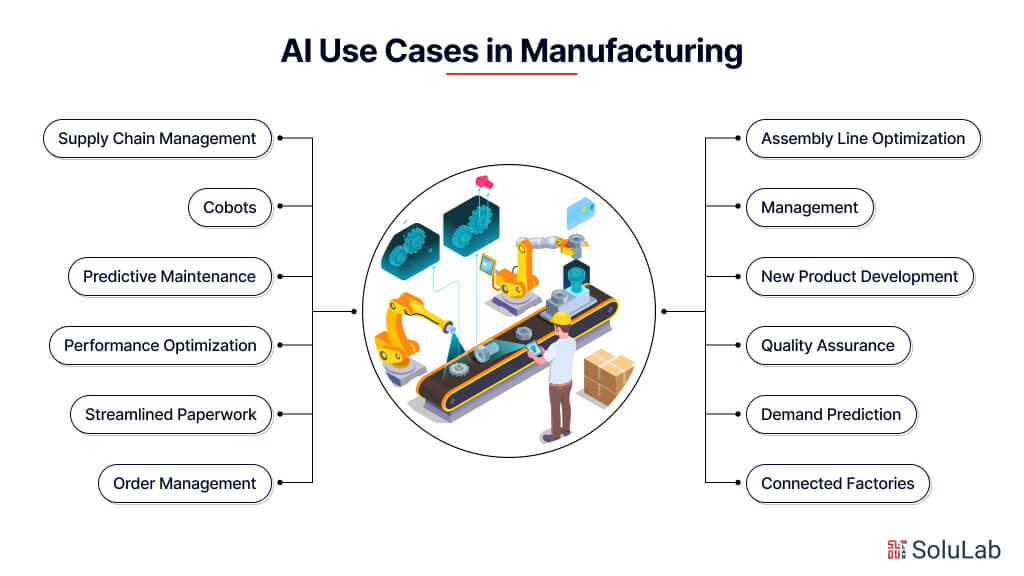

Top 12 AI Use Cases in Manufacturing

Here are some of the top use cases of AI in manufacturing:

1. Supply Chain Management

In the manufacturing sector, supply chain management is critical, and AI has changed the game in this area. Businesses are reinventing their supply chain operations and generating notable gains in efficiency, accuracy, and cost-effectiveness by utilizing the potential of AI solutions for manufacturing.

Utilizing AI for manufacturing in the supply chain makes it possible to improve demand forecasting, streamline logistics, optimize inventory management, and leverage predictive analytics. Machine learning in manufacturing can examine past data, spot trends, and forecast demand variations with precision.

An automobile parts company, for example, may estimate spare part demand using ML models, which enables them to manage inventory levels and cut costs. Additionally, the company uses AI-powered routing algorithms to improve logistics, resulting in quicker and more affordable delivery. Walmart’s integration of manufacturing and AI into supply chain operations is a prime example of how modern technologies improve decision-making, responsiveness, and global supply chain resilience in the highly competitive retail industry.

2. Cobots

Collaborative robots, also known as cobots, are essential for AI-driven production because they boost output by working alongside human operators. AI for manufacturing is utilized by cobots assist in selecting and packing at fulfillment facilities. Together with human workers, these cobots use AI algorithms to detect items and navigate complex environments.

For example, machine learning is used by Amazon’s cobots to optimize operations, accelerate order fulfillment, and simplify logistics. These AI-powered robots are capable of accurately and adaptably completing difficult jobs. Cobots can operate in unison with human workers to conduct complex assembly procedures and quality control checks. This preventive approach guarantees maximum equipment performance, lowers maintenance costs, and limits downtime.

This cooperative approach is a great example of how manufacturing and AI may be used to build a more flexible and productive manufacturing environment where operational excellence depends on human-machine cooperation.

3. Management

In the management industry, manufacturing AI is also transforming the administration of warehouses. Warehouse operations have changed as a result of the introduction of AI-powered manufacturing solutions and machine learning, which have increased productivity, accuracy, and cost savings.

Inventory management is a key AI manufacturing application case for warehouses. In order to precisely forecast demand patterns, AI systems may examine previous sales data, present stock levels, and market trends. This helps warehouses to maintain product availability while cutting carrying costs by optimizing inventory levels.

For example, BMW utilizes AI-powered automated guided vehicles (AGVs) to improve intralogistics in its production warehouses. By automating the delivery of materials and completed goods along preset routes, these AGVs improve inventory visibility and management for the business. The use of AI in manufacturing industry has resulted in substantial breakthroughs in warehouse management. From inventory management to simplified order fulfillment, AI-powered manufacturing and machine learning technologies are reshaping warehouses, enabling them to become more efficient and cost-effective.

4. Assembly Line Optimization

Manufacturing AI uses AI to increase the precision, effectiveness, and adaptability of manufacturing operations. Machine learning algorithms enhance efficiency, decrease downtime, and allow predictive maintenance by evaluating historical performance measurements and real-time sensor data. AI-driven computer vision systems can spot defects or abnormalities to guarantee product quality.

Intelligent automation reduces waste and maximizes resource use by altering production settings in response to changes in demand. Through continuous learning and adaptation, AI in manufacturing industry transforms assembly lines into data-driven, adaptable environments that ultimately increase productivity, reduce costs, and maintain high standards in manufacturing processes.

In the manufacturing 5.0 sector, Volkswagen is a well-known company that uses artificial intelligence to optimize assembly lines. They use AI-driven solutions to raise the standard and efficacy of their manufacturing processes. Volkswagen uses machine learning algorithms to examine sensor data from the assembly line in order to estimate repair needs and optimize operations.

5. Predictive Maintenance

Artificial intelligence applications have made predictive maintenance a major changer in the manufacturing sector. Artificial Intelligence in manufacturing industry helps businesses to anticipate and proactively monitor equipment breakdowns, reducing downtime and improving maintenance schedules. This is achieved by utilizing sophisticated predictive analytics and machine learning algorithms.

The digital twin is one important predictive maintenance idea. An electronic duplicate of a physical item that records data in real-time and replicates its actions in a virtual setting is called a digital twin. AI for manufacturing sector may evaluate trends, spot abnormalities, and anticipate possible breakdowns by fusing sensor data from the equipment with the digital counterpart.

Predictive maintenance in the manufacturing sector is changing dramatically thanks to artificial intelligence. Businesses may use data to forecast equipment breakdowns, optimize maintenance schedules, and thereby boost operational efficiency and cost-effectiveness by leveraging digital twins and advanced analytics. This is in line with current AI Trends and highlights the future of artificial intelligence in transforming industries.

6. New Product Development

With the introduction of AI, the manufacturingl industry’s ability to produce new goods has undergone a dramatic change. Artificial Intelligence (AI) integration in the manufacturing sector has resulted in creative solutions and optimized workflows that are transforming how businesses develop and launch new goods.

For instance, semiconductor businesses may detect possible problems in new designs, identify component failures, and suggest ideal layouts to increase yield in IC design by utilizing machine learning in production. For example, NVIDIA analyzes massive datasets on component architectures using machine learning methods, which enables it to anticipate problems with future chip designs and pinpoint potential failure sites.

They accelerate time to market by improving semiconductor layouts, reducing costs, and raising yields by utilizing AI-based data. This application shows how artificial intelligence (AI) may help with data-driven decision-making and development in semiconductor manufacturing sector product development processes. This aligns with AI Trends and underscores the future of artificial intelligence in driving innovation.

7. Performance Optimization

Artificial intelligence is a major changer in the manufacturing industry, and performance optimization is essential. Through the analysis of historical data, real-time sensor data, and other pertinent factors, AI systems are able to recognize trends, discover anomalies, and create data-driven predictions. Manufacturers are able to increase overall equipment effectiveness, eliminate downtime, and improve operations as a result.

One real-world example of how AI use cases and applications affects manufacturing performance improvement is General Electric (GE). In order to evaluate vast amounts of data from sensors and historical records, GE has incorporated AI algorithms into its production processes. GE uses AI to identify patterns, forecast potential equipment problems, and optimize workflows. GE may decrease equipment downtime, increase overall equipment effectiveness, and enhance the efficacy of manufacturing processes by adopting this proactive strategy. This showcases the potential of GenAI in manufacturing.

8. Quality Assurance

Companies are reinventing their approach to quality control by using the potential of artificial intelligence in manufacturing, assuring more precision and consistency. AI allows manufacturers to use computer vision algorithms to examine photos or videos of goods and components. These algorithms can detect faults, abnormalities, and deviations from quality norms with unprecedented precision, far beyond human skills.

Foxconn, a leading electronics manufacturer, is a real-world example of a company that uses AI use cases and applications in production to regulate quality. Foxconn has enhanced quality control methods by adding AI and computer vision technology into its manufacturing lines. Artificial intelligence (AI) systems may discover faults in electrical components by analyzing images and videos, guaranteeing that the items meet stringent quality requirements.

AI in quality control improves manufacturing efficiency and accuracy, helping companies like Foxconn to manufacture high-quality products on a broad scale in the ever-evolving electronics industry. Furthermore, GenAI in manufacturing improve predictive quality assurance. ML algorithms discover patterns and trends in historical and real-time sensor data, which may suggest possible quality concerns. This allows producers to identify any problems and take remedial action before they affect the final product’s quality.

9. Streamlined Paperwork

One significant use of AI and ML in manufacturing includes the implementation of robotic process automation (RPA) for paperwork automation. In the past, manufacturing processes need a large amount of paperwork, which includes purchase orders, invoices, and quality control reports. These manual operations are tedious, error-prone, and can cause delays and inefficiencies.

Companies may automate these administrative procedures by incorporating conversational AI into their manufacturing operations. Intelligent bots with AI skills are able to gather data from documents, organize and categorize it, and enter it into the proper systems.

For example, Whirlpool uses RPA to automate manufacturing operations, notably assembly line and material handling jobs. RPA bots perform repetitive and rule-based operations, ensuring accuracy and productivity during this manufacturing process.

Whirlpool also uses these bots for quality control checks, using automation to increase consistency and accuracy in assessing final products. This highlights the Power of AI in enhancing efficiency. Furthermore, AI in supply chain management plays a significant role, as it helps companies like Whirlpool optimize operations and maintain a high level of quality in its products by automating quality assurance tasks.

10. Demand Prediction

The application of artificial intelligence in manufacturing for demand forecast has several advantages. It primarily allows businesses to make data-driven decisions by reviewing past sales data, market trends, and external influences.

This allows them to predict changes in demand and modify production appropriately, lowering the risk of stockouts or surplus inventory.

Assume a fashion products firm that uses AI to estimate demand for various apparel items. The AI system can deliver accurate predictions by evaluating data from numerous sources, including social media trends, weather forecasts, and consumer preferences, allowing the merchant to manage inventory levels and assure the availability of popular products.

AI in supply chain management is crucial here, as it helps in optimizing inventory levels and ensuring timely availability of products. The Power of AI in demand forecasting showcases its ability to significantly enhance operational efficiency and responsiveness in the manufacturing industry.

11. Order Management

Utilizing Artificial Intelligence (AI) in order management means improving and simplifying the whole order fulfillment process. To accurately forecast demand, AI manufacturing studies historical data, customer preferences, and industry trends using AI application in manufacturing machine learning algorithms. This enables automated order processing, inventory optimization, and dynamic pricing adjustments. Additionally, AI increases fraud detection, reducing the risks associated with fraudulent orders.

By streamlining repetitive operations and providing data-driven insights, AI in manufacturing improves the overall efficiency of order management systems, accelerates decision-making, and ensures a more receptive and customer-centric approach to order fulfillment for businesses across multiple industries.

The IBM Watson Order Optimizer is a practical use of artificial intelligence in order management. IBM’s technology solution uses AI/ML algorithms to assess previous order data, consumer behavior, and other external factors. By exploiting these data, the system improves order fulfillment operations, dynamically adjusts inventory levels, and suggests optimal order routing options. This helps businesses save expenditures, boost client happiness, and enhance order management efficiency.

12. Connected Factories

Connected factories are excellent examples of how artificial intelligence may be integrated into manufacturing processes to create intelligent, networked systems. Using IoT sensors, manufacturers may use AI and manufacturing to examine real-time data from machines, predict maintenance requirements, simplify operations, and decrease downtime.

This networked system enables efficient machine-to-machine communication, allowing for rapid adjustments to production schedules as a consequence to changes in demand. Predictive analytics improves decision-making and ensures smooth operations. Finally, AI-powered connected factories save costs, improve overall operational efficiency, and raise productivity by establishing data-driven, adaptable manufacturing ecosystems that respond swiftly to changing situations.

General Electric (GE) is one well-known example of a company that is embracing AI-based networked factories. The company employs its Predix platform for incorporating artificial intelligence (AI) and the Internet of Things (IoT) in manufacturing.

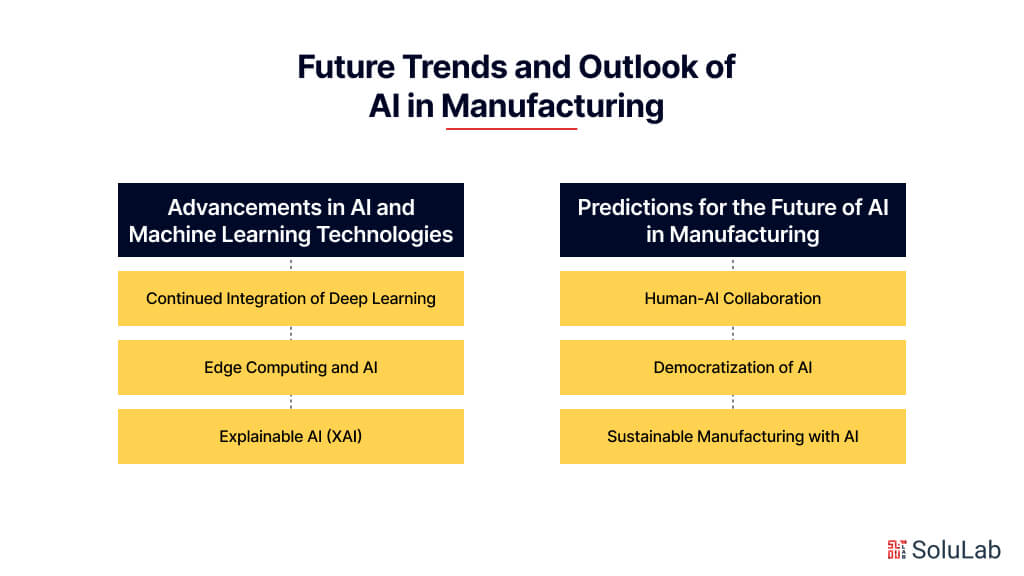

Future Trends and Outlook of AI in Manufacturing

As manufacturing continues to evolve in the digital age, the integration of AI and manufacturing stands at the forefront of transformative change. With rapid advancements in AI and machine learning technologies, the future of manufacturing holds unprecedented potential for innovation, efficiency, and competitiveness. In this section, we explore the ai in manufacturing advancements and predictions shaping the future of AI in manufacturing. From advancements in AI algorithms to the proliferation of autonomous systems, let’s delve into the exciting possibilities that lie ahead.

Advancements in AI and Machine Learning Technologies

1. Continued Integration of Deep Learning: As deep learning techniques mature, they will play an increasingly significant role in optimizing manufacturing processes. Advanced neural networks and deep reinforcement learning algorithms will enable more sophisticated decision-making capabilities within AI systems.

2. Edge Computing and AI: The rise of edge computing will bring AI capabilities closer to the manufacturing process, allowing for real-time data processing and decision-making at the source. This trend will reduce latency, enhance scalability, and improve overall system reliability.

3. Explainable AI (XAI): With the growing complexity of AI systems in manufacturing, there will be a greater emphasis on developing explainable AI models. Manufacturers will demand transparency and interpretability in AI-driven decision-making processes to build trust and facilitate regulatory compliance.

Predictions for the Future of AI in Manufacturing

1. Human-AI Collaboration: The future of manufacturing will involve closer collaboration between humans and AI systems. While AI will handle repetitive tasks and decision-making processes, human workers will focus on higher-level strategic planning, creativity, and problem-solving.

2. Democratization of AI: As AI technologies become more accessible and user-friendly, smaller manufacturers and startups will increasingly adopt AI solutions to remain competitive. Cloud-based AI platforms and pre-built AI modules will democratize access to advanced AI capabilities, leveling the playing field in the manufacturing industry.

3. Sustainable Manufacturing with AI: AI will play a pivotal role in driving sustainability initiatives within manufacturing. By optimizing energy consumption, reducing waste, and optimizing resource usage, AI-powered systems will help manufacturers minimize their environmental footprint while maximizing operational efficiency.

Conclusion

In summary, the application of artificial intelligence (AI) to manufacturing is an important change that is opening up new opportunities for efficiency and development while also altering established processes. As we’ve seen, AI-driven solutions provide unmatched chances for supply chain efficiency, predictive maintenance, quality control, and other areas. As artificial intelligence (AI) technology progresses and novel applications arise, firms stand to gain from heightened efficiency, reduced expenses, and improved competitiveness in a dynamic market environment.

Are you looking to utilize artificial intelligence (AI) in your manufacturing processes? Being a top AI development company, SoluLab is efficient in providing modern solutions that are specifically designed to meet the demands of the manufacturing sector. Whether you’re seeking to optimize production processes, implement predictive analytics, or enhance operational efficiency, hire AI developers from SoluLab now! Contact us today to unlock the full potential of AI in manufacturing and propel your business toward a brighter future.

FAQs

1. What are some common AI applications in manufacturing?

AI applications in manufacturing include predictive maintenance, quality control, supply chain optimization, and production scheduling. These AI-driven solutions help enhance efficiency, reduce downtime, and improve product quality.

2. How is AI transforming the manufacturing industry?

AI in the manufacturing industry is revolutionizing processes by enabling real-time data analysis, automating routine tasks, and providing insights for better decision-making. This leads to increased productivity, reduced costs, and improved safety.

3. Can you provide examples of AI in manufacturing?

Examples of AI in manufacturing include using machine learning for predictive maintenance, deploying computer vision for quality inspection, and utilizing AI algorithms for supply chain management and demand forecasting.

4. What is the future of artificial intelligence in manufacturing?

The future of AI in manufacturing involves more advanced AI applications such as GenAI for design optimization, AI-driven robotics for more complex tasks, and enhanced AI integration in supply chain management to create more responsive and adaptive manufacturing systems.

5. How does AI benefit supply chain management in manufacturing?

AI in supply chain management enhances efficiency by predicting demand, optimizing inventory levels, identifying potential disruptions, and improving logistics planning. This ensures a smoother and more cost-effective supply chain.

6. What are some AI use cases and applications in manufacturing?

AI use cases in manufacturing include automated visual inspection for quality control, predictive analytics for machinery maintenance, AI-powered robotics for assembly lines, and AI-driven decision support systems for production planning.

7. How does GenAI impact manufacturing?

GenAI in manufacturing impacts areas such as product design, process optimization, and predictive maintenance. By leveraging generative AI models, manufacturers can explore new designs, simulate production processes, and predict equipment failures with greater accuracy.