For years, AI was just seen on screens, like chatbots responding to queries, dashboards displaying insights, and algorithms generating suggestions. But now the scene is changing. With its ability to perceive, move, react, and act instantly, artificial intelligence is beginning to enter the real life scenarios. This shift is due to increased demand for automation, efficiency, and better decision-making in real-world settings such as factories, cities, hospitals, and more.

This evolution is being driven by advanced AI development and integration services with a blend of smarter hardware. Wherein, AI development builds intelligence models, and AI integration enables quick and dependable action– combined with hardware systems, they transform AI from a virtual assistant into a real-world problem-solver.

Let’s delve deeper to get a better understanding!

Key Takeaways

- Physical AI moves AI beyond software, enabling systems to sense, decide, and act in real-world environments.

- AI development provides the intelligence, while AI integration makes that intelligence operational in physical systems.

- Successful Physical AI requires tight coordination between hardware, software, edge, and cloud infrastructure.

What Is Physical AI?

As the name indicates, “physical AI” means smart AI-powered systems that can see, hear, and do things in the real environment. Physical AI is different from traditional AI since it can work with machines, gadgets, and autonomous systems in the real world, not only software programs and dashboards. It uses AI and hardware together so that computers may respond to things that happen in the actual world, not just data on a screen.

In simple terms, Physical AI is AI that does things, not just analyzes.

Core Components of Physical AI

Physical AI systems are built by combining multiple technologies that work together:

1. Sensors & IoT Devices: Cameras, microphones, LiDAR, GPS, and environmental sensors that collect real-world data.

2. AI Models: Machine learning, computer vision, and reinforcement learning models that interpret data and make decisions.

3. Edge & Cloud Infrastructure: Edge computing enables real-time responses, while cloud platforms support training, storage, and scalability.

4. Actuators & Hardware Systems: Robots, machines, vehicles, or control systems that execute AI-driven actions.

5. Integration Layer: Software frameworks and APIs that connect AI models with hardware, data pipelines, and enterprise systems.

Traditional AI Software vs Physical AI Systems

| Aspect | Traditional AI Software | Physical AI Systems |

| Primary Function | Analyze data and generate insights | Sense, decide, and act in the real world |

| Environment | Digital (apps, dashboards, platforms) | Physical environments (factories, roads, cities) |

| Real-Time Requirements | Low to moderate | High, often mission-critical |

| Hardware Dependency | Minimal | High (sensors, devices, machines) |

| Risk Level | Lower | Higher due to safety and reliability needs |

| Integration Complexity | Mostly software-based | Software + hardware + edge integration |

Why Physical AI Cannot Work Without AI Development?

Physical AI is not just about connecting machines or setting up automation rules. The real world is messy and unpredictable– lighting changes, objects move, conditions shift, and systems face situations they’ve never seen before. A physical system breaks when something unexpected occurs since it can only follow predefined instructions. Wherein AI development empowers Physical AI to comprehend its surroundings and determine its subsequent actions.

With AI development, Physical AI systems can:

- Perceive their surroundings using computer vision, audio analysis, and sensor data

- Recognize patterns and spot anomalies as they happen

- Make context-aware decisions, not just rule-based responses

- Learn and improve over time from new data and real-world interactions

In Physical AI use cases, like autonomous robots, smart traffic control, or intelligent manufacturing, generic, pre-built models simply don’t work because each environment has its own variables, risks, and performance expectations. That is why custom AI development is required– to train models for specific conditions, safety requirements, and operational goals.

To put it simply, hardware gives Physical AI a body to execute functions, but AI development gives it a brain to adapt, scale, or deliver real value in the physical world.

Why AI Integration Is Essential for Physical AI?

Without a flawless AI integration, even the most accurate AI is isolated and useless in real-world situations. In order for physical AI to function smoothly in real time, intelligence must move between sensors, systems, and devices.

AI integration makes this possible by:

- Connecting AI models with physical devices such as sensors, cameras, robots, and IoT systems

- Enabling real-time data pipelines so decisions are made instantly, not after delays

- Linking edge, cloud, and on-prem systems for reliable performance and scalability

- Ensuring safe and controlled execution of AI-driven actions in physical environments

In Physical AI systems, even milliseconds hold much significance; poor AI integration can cause latency, data loss, or system failures, risks that are unacceptable in sectors like factories, healthcare, transportation, or smart cities.

This is why Physical AI succeeds only when the finest AI integration services combine intelligence and execution, eventually converting AI insights into precise, real-world actions that are executed at the right time.

AI Development vs AI Integration: What Enterprises Need to Know

Enterprises must understand the difference between building intelligence and deploying it in the real world for a successful Physical AI project. Because AI development and AI integration serve distinct functions but play equally important roles. Let’s see the major difference points:

Key Differences

| Aspect | AI Development | AI Integration |

| Primary Focus | Creating intelligent models and algorithms | Embedding AI into physical and enterprise systems |

| Core Activities | Data preparation, model training, testing, optimization | Connecting AI with hardware, software, and workflows |

| Output | Trained AI models | Fully functioning Physical AI systems |

| Skill Set Required | Data science, machine learning, AI engineering | Systems engineering, IoT, edge computing, APIs |

| Business Impact | Improves decision accuracy | Enables real-time action and scalability |

| Risk if Missing | No intelligence or adaptability | AI remains isolated and unusable |

Physical AI in Enterprise vs Startup Environments

Physical AI is not the same for everyone. How it’s built and deployed depends a lot on whether the team behind it is a startup or a large enterprise. While both use Physical AI to improve real-world operations, their goals, pressures, and ways of executing are very different.

Startups usually move fast. They use Physical AI to test ideas, validate use cases, attract investors, or solve a very specific problem. Speed and experimentation matter more than perfection for such businesses. However, big enterprises have long-term plans, so their major focus is on reliability, scalability, security, and compliance. This is because Physical AI systems often support critical operations where failure isn’t an option.

Understanding these differences helps teams choose the right AI development and integration approach from the start:

| Aspect | Startups | Enterprises |

| Primary Goal | Validate idea and achieve product-market fit | Optimize operations at scale |

| Time to Market | Fast and iterative | Planned and phased |

| System Complexity | Limited scope, focused use cases | High complexity across departments |

| Infrastructure | Cloud-first, lightweight setups | Hybrid or on-prem with edge systems |

| AI Development Approach | MVP-focused, experimental models | Custom, production-grade AI models |

| Integration Needs | Basic device and API integration | Deep integration with legacy systems |

| Risk Tolerance | Higher | Lower, with strong safety requirements |

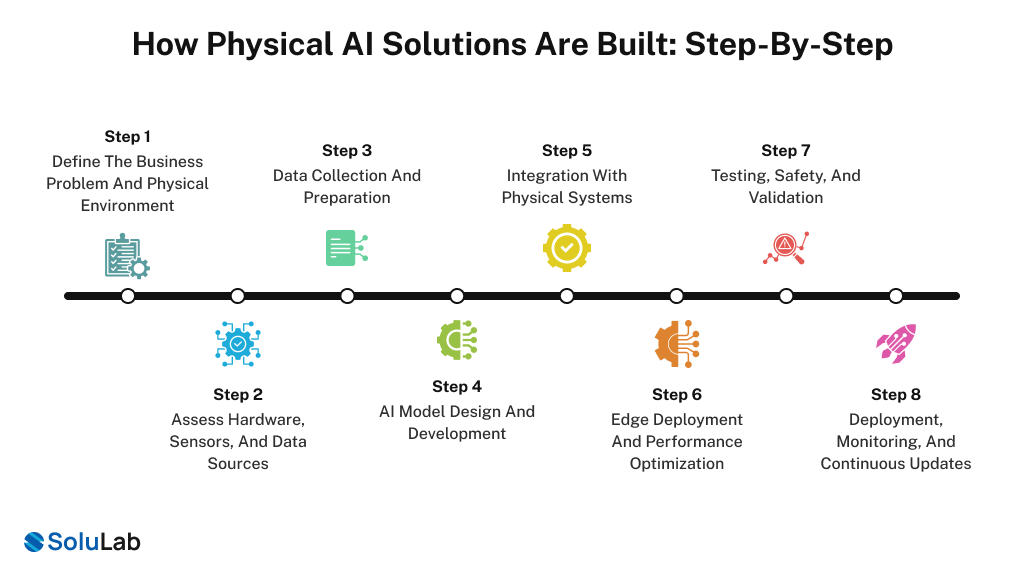

How Physical AI Solutions Are Developed: A Step-by-Step Guide

Developing a physical AI solution requires a robust strategy that makes a balance between hardware, intelligence, and practical limitations. Every phase makes sure that the technology works well outside of controlled situations.

Step 1. Define the Business Problem and Physical Environment

The first step is clearly identifying what the Physical AI system needs to achieve. This includes understanding:

- The real-world task to be automated or optimized

- Environmental conditions such as lighting, noise, movement, and safety constraints

- Performance expectations like speed, accuracy, and reliability

A well-defined problem prevents overengineering and sets measurable success criteria.

Step 2. Assess Hardware, Sensors, and Data Sources

Physical AI depends heavily on real-world data. This step focuses on:

- Selecting sensors (cameras, LiDAR, microphones, temperature, motion sensors, etc.)

- Evaluating hardware compatibility and limitations

- Mapping how data will be collected, transmitted, and stored

Poor sensor choices can limit AI accuracy, no matter how advanced the model is.

Step 3. Data Collection and Preparation

Once hardware is in place, real-world data is gathered to train AI models. This involves:

- Capturing diverse and representative datasets

- Cleaning noisy or incomplete sensor data

- Labeling data for supervised learning tasks

- Handling edge cases and rare events

High-quality data is the foundation of effective Physical AI.

Step 4. AI Model Design and Development

At this stage, intelligence is built into the system by:

- Selecting suitable AI techniques (computer vision, reinforcement learning, predictive models)

- Training and testing models on collected data

- Optimizing models for accuracy, speed, and robustness

- Validating performance under real-world conditions

Custom AI development ensures models are tailored to specific physical environments.

Step 5. Integration with Physical Systems

This is where Physical AI becomes operational. Integration includes:

- Connecting AI models to sensors, devices, and actuators

- Building real-time data pipelines

- Integrating with control systems, robotics, or enterprise software

- Ensuring reliable communication between edge and cloud components

Strong integration is critical to prevent delays, errors, or system failures.

Step 6. Edge Deployment and Performance Optimization

Many Physical AI systems must operate in real time. This step focuses on:

- Deploying AI models on edge devices for low-latency decisions

- Optimizing models to run within hardware constraints

- Balancing workloads between edge and cloud environments

This ensures fast response times and uninterrupted operations.

Step 7. Testing, Safety, and Validation

Before full-scale deployment, systems are rigorously tested to:

- Simulate real-world scenarios and failure conditions

- Validate safety mechanisms and fallback processes

- Ensure compliance with industry regulations and standards

Testing reduces risk and builds confidence in production environments.

Step 8. Deployment, Monitoring, and Continuous Updates

After deployment, Physical AI systems must evolve. This includes:

- Monitoring performance and system health in real time

- Collecting new data for retraining models

- Updating AI behavior as environments and requirements change

Continuous learning ensures the system remains accurate, safe, and effective over time.

How Expert AI Development and Integration Accelerate Physical AI?

Physical AI solutions may fail at times owing to implementation flaws as well as poor concepts. Expert AI development and integration services lower these risks by effectively transforming complex ideas into dependable, practical systems.

Experienced AI teams accelerate Physical AI by:

- Designing the right AI architecture from day one, aligned with physical constraints and business goals

- Building custom AI models that are optimized for specific environments, devices, and use cases

- Reducing trial-and-error through proven development frameworks and reusable components

On the integration side, experts ensure:

- Seamless connection between AI models and physical systems, avoiding latency and data bottlenecks

- Efficient edge and cloud deployment, enabling real-time decisions without compromising scalability

- Early risk identification, especially around safety, system failure, and performance limits

Overall, right integration and development reduce operational risk, speed up development cycles, and increase return on investment. Instead of dealing with fragmented tools or experimental setups, organizations benefit from production-ready Physical AI systems that scale quickly and excel in real-world scenarios.

How SoluLab Helps Build and Integrate Physical AI Solutions?

Building Physical AI requires a partner who understands AI intelligence, system integration, and real-world execution together. That’s where SoluLab comes in. We support businesses across the full Physical AI lifecycle:

1. Strategic AI Consulting

Our AI consulting services assess your use case, physical environment, and operational goals to define the right Physical AI roadmap—whether you need a pilot, scalable deployment, or enterprise-grade system.

2. Custom AI Development

Our teams build tailored AI models for computer vision, predictive analytics, reinforcement learning, and edge AI– trained on real-world data for accuracy, safety, and performance.

3. End-to-End AI Integration

We seamlessly integrate AI with sensors, IoT devices, robotics, edge hardware, and enterprise platforms to ensure real-time, reliable decision-making.

4. Edge, Cloud, and Hybrid Deployment

We optimize Physical AI systems for low latency and scalability by balancing workloads across edge and cloud infrastructure.

With a strong focus on execution, scalability, and ROI, SoluLab helps organizations move beyond experimentation and deploy Physical AI solutions that work reliably in the real world.

Final Thoughts

Physical AI represents a significant transition in how organizations use artificial intelligence, from insights on screens to intelligence that acts in the actual world. However, this change will only be successful if AI is developed with a thorough understanding of physical settings and seamlessly incorporated into real-world systems.

Robust AI development gives physical AI the intelligence it needs to see, understand, and make decisions. The secure, real-time, and large-scale operation of intelligence is assured by expert AI integration. Early investments in solid strategy, technology, and execution will enable quicker decision-making, safer systems, and sustained operational benefits.

Talk to our AI experts and start building production-ready Physical AI solutions today!

FAQs

Physical AI is best for problems that require real-time decision-making in dynamic environments. This includes tasks like autonomous movement, predictive maintenance, real-world quality inspection, traffic optimization, and intelligent robotics—where conditions constantly change and rule-based automation fails.

Timelines depend on complexity, environment, and integration depth. A focused pilot can take a few months, while enterprise-scale deployments often follow phased rollouts over 6–12 months. Starting with the right architecture significantly reduces delays later.

No. While robotics is a common use case, Physical AI also powers smart infrastructure, connected healthcare systems, logistics optimization, autonomous inspection, and real-time monitoring across industries.

SoluLab focuses on building production-ready Physical AI, not experiments. The approach combines strategic consulting, custom AI development, and deep system integration to ensure solutions are reliable, scalable, and aligned with business goals.

Yes. SoluLab helps organizations start with focused pilots to validate value, then scales those solutions into enterprise-grade Physical AI systems with long-term support and optimization.