In a world of manufacturing and production, the pursuit of uncompromised quality has long been a cornerstone. As industries strive to deliver products that meet and exceed consumer expectations, the role of visual quality control has become increasingly pivotal. In this era of rapid technological advancement, Artificial Intelligence (AI) emerges as a transformative force, revolutionizing the traditional paradigms of quality assurance.

In this blog, we will delve into the dynamic role of AI in Visual Quality Control, unraveling the profound impact AI technologies have on enhancing precision, efficiency, and overall efficacy in ensuring product quality. From streamlining inspection processes to identifying nuanced defects that elude the human eye, AI is poised to reshape the way industries approach quality control, setting new benchmarks for excellence.

So, let’s get started!

The Transformative Impact of AI on Visual Inspection for Quality Control

Visual Quality Control (VQC) stands as a foundational pillar in the realm of quality assurance across diverse industries, serving as a critical mechanism to uphold pre-defined quality benchmarks through the evaluation of visual attributes. This method of quality control capitalizes on the synergy between human visual perception and cutting-edge technologies, with a particular emphasis on Artificial Intelligence (AI) and computer vision. By harnessing these advanced tools, VQC meticulously identifies defects, inconsistencies, and deviations in the visual characteristics of products.

At its core, VQC scrutinizes products or objects by relying on their visual attributes, meticulously assessing them against established quality standards. This comprehensive evaluation encompasses a spectrum of visual elements, including color, texture, shape, dimensions, surface finish, labeling, and overall appearance.

The primary goal of VQC is to pinpoint defects, irregularities, and deviations that have the potential to impact a product’s functionality, safety, aesthetics, and market viability. In this context, the integration of AI in visual inspection emerges as a game-changer, enhancing the precision and efficiency of the quality control process, and ensuring that even the subtlest visual discrepancies are identified with unparalleled accuracy.

The Importance of Visual Quality Control: Harnessing AI for Enhanced Assessments

Within various industries, the importance of Visual Quality Control (VQC) cannot be overstated when it comes to upholding product integrity and safeguarding brand reputation. This method relies on the acute sensitivity of human visual perception and integrates advanced technologies, including the pivotal use of AI and computer vision, for a thorough evaluation of products against predefined quality standards. Incorporating the use of AI in Visual Quality Control proves indispensable in the timely detection of defects and irregularities, acting as a preventive measure against potential customer dissatisfaction, costly recalls, increased expenditures, and reputational damage. By facilitating prompt corrective actions during production, this collaborative approach ensures the consistent delivery of products that not only meet visual and functional expectations but also fortify consumer trust in the brand.

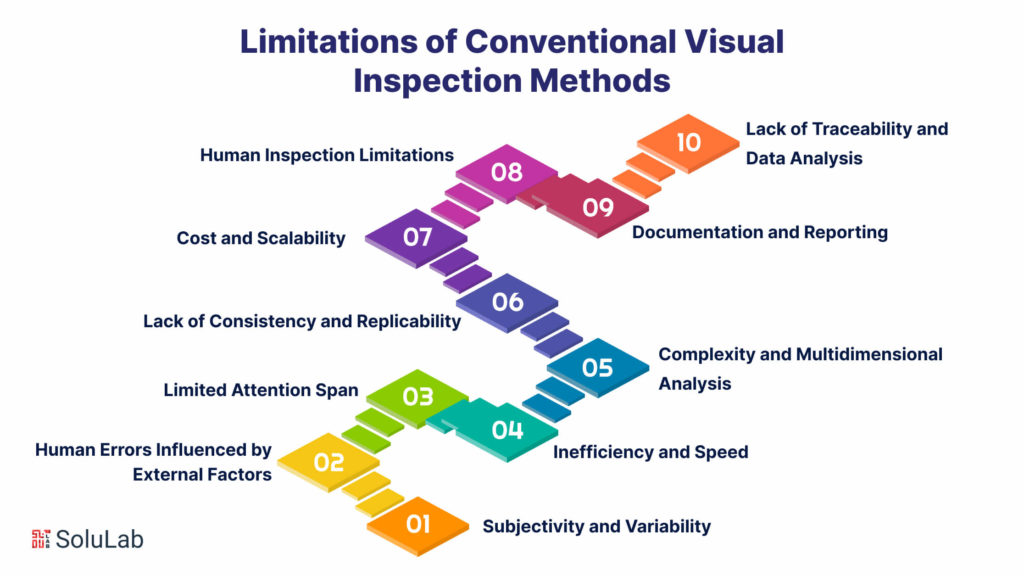

Limitations of Conventional Visual Inspection Methods

Traditional visual inspection, while serving as a valuable quality control method, confronts notable challenges. Human-centric visual inspections are encumbered by limitations that can give rise to errors, disparities, and inefficiencies. In this discussion, we will explore the hurdles associated with conventional visual inspection processes, specifically focusing on Subjectivity and human errors:

-

Subjectivity and Variability

Human inspectors are susceptible to subjective judgments and variations in their assessments. What one inspector may identify as a defect, another might either overlook or interpret differently. This inherent subjectivity introduces inconsistency in quality assessments, posing a challenge to uniform standards.

-

Human Errors Influenced by External Factors

Factors such as fatigue, distraction, and even mood can significantly impact an inspector’s accuracy. The vulnerability to these external influences increases the likelihood of errors in judgment, further emphasizing the need for a more robust and reliable inspection process.

-

Limited Attention Span

Visual inspections demand sustained focus, which becomes challenging for human inspectors over extended periods. Fatigue can compromise an inspector’s ability to accurately identify defects, especially in industries requiring rapid examination of numerous items.

-

Inefficiency and Speed

Traditional visual inspections, particularly in high-volume scenarios, can be time-consuming. Manual inspections may impede production lines, affecting overall efficiency, as each product requires individual visual examination.

-

Complexity and Multidimensional Analysis

Some defects may elude human inspectors due to their complexity or the need for multidimensional analysis. Products with intricate designs or internal components may necessitate analytical approaches beyond the capabilities of human vision alone.

-

Lack of Consistency and Replicability

Replicating assessments consistently across different sessions proves challenging for human inspectors. Variables like lighting conditions and individual mood can introduce inconsistencies in results.

-

Cost and Scalability

Training and maintaining a skilled workforce of inspectors can be costly, particularly in cases requiring specific domain knowledge. As production scales up, the expenses associated with employing more inspectors can become prohibitive.

-

Human Inspection Limitations

Certain quality aspects, such as microscopic defects or issues beyond the visible spectrum, pose challenges to human vision. This limitation may lead to undetected defects affecting overall product quality.

-

Documentation and Reporting

Keeping track of inspection results and generating accurate reports is laborious and error-prone. Translating visual observations into structured data for analysis proves challenging without the use of automated systems.

-

Lack of Traceability and Data Analysis

Conventional visual inspection methods often lack robust data collection and analysis capabilities. This deficiency hinders the identification of trends, patterns, and root causes of defects over time.

In response to these challenges, industries increasingly turn to technology, particularly AI and computer vision, as a solution. AI-driven systems address the limitations associated with human-based inspections, offering enhanced accuracy, consistency, speed, and the ability to analyze complex visual data. These technological advancements have the potential to redefine quality control practices and elevate overall product quality.

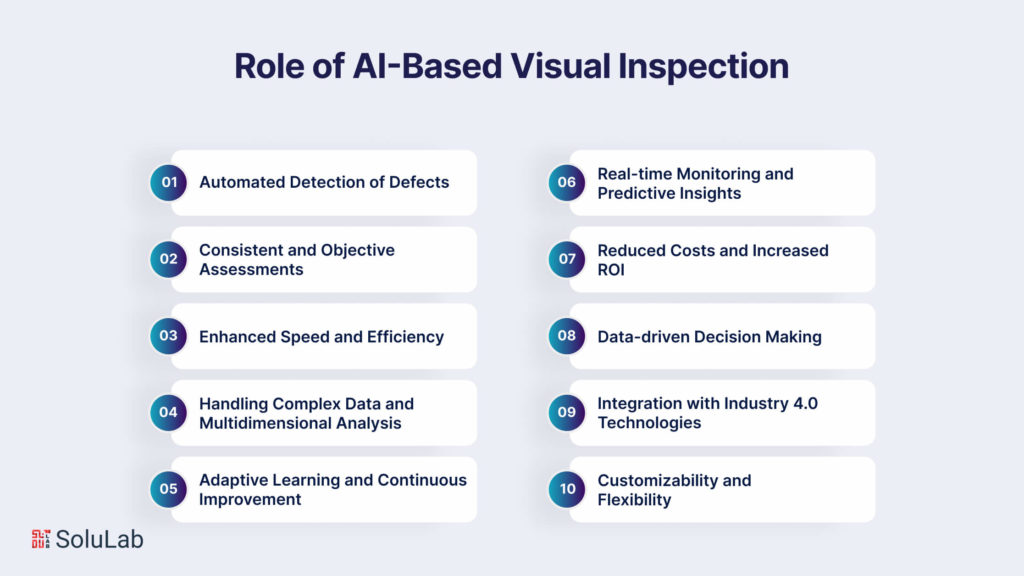

The Role of AI-Based Visual Inspection

Artificial Intelligence (AI) is driving a transformative wave across diverse industries, with one notable arena being Visual Quality Control. Through the integration of AI technologies like Machine Learning (ML) and computer vision, enterprises are experiencing heightened precision, efficiency, and efficacy in their quality control processes.

Here’s an in-depth exploration of how AI reshapes Visual Quality Control:

1. Automated Detection of Defects: AI-powered systems excel at discerning subtle defects that may challenge human inspectors. By training ML models on extensive datasets, these systems can recognize patterns associated with defects, ensuring early detection and preventing faulty products from reaching consumers.

2. Consistent and Objective Assessments: AI eliminates subjectivity, providing consistent assessments based on predefined criteria. This objectivity enhances quality control outcomes, reducing disputes or inconsistencies in judgments.

3. Enhanced Speed and Efficiency: AI-driven Visual Quality Control surpasses manual inspections in speed. Automated systems analyze visual data in real time, enabling high-speed inspections without compromising accuracy, especially beneficial in fast-paced production lines.

4. Handling Complex Data and Multidimensional Analysis: AI algorithms process and analyze complex visual data, such as high-resolution images or 3D scans, enabling the detection of intricate defects beyond human vision.

5. Adaptive Learning and Continuous Improvement: AI systems learn and improve over time, adapting to new data and identifying emerging defects. This adaptability is crucial for addressing evolving quality challenges.

6. Real-time Monitoring and Predictive Insights: AI-equipped systems offer real-time monitoring, alerting operators to deviations from quality standards for immediate corrective actions, reducing the propagation of defects.

7. Reduced Costs and Increased ROI: While the initial investment is significant, AI-driven systems lead to substantial cost savings by reducing manual inspections, minimizing defective products, and preventing costly recalls.

8. Data-driven Decision Making: AI generates data for informed decision-making, facilitating the identification of root causes of defects and targeted process improvements.

9. Integration with Industry 4.0 Technologies: AI-driven quality control seamlessly integrates with Industry 4.0 technologies like robotics and the Internet of Things (IoT), enhancing analysis with additional sensor data and automating product handling during inspection.

10. Customizability and Flexibility: AI systems can be tailored to identify defects specific to products or industries, providing organizations with a customized approach to quality control.

In essence, the integration of visual inspection AI revolutionizes quality control, offering a comprehensive solution to address the challenges associated with traditional methods.

AI Visual Inspection: Transformative Applications Across Industries

AI-driven Visual Quality Control has emerged as a revolutionary catalyst, reshaping traditional quality assurance processes and setting new benchmarks for product excellence across diverse industries. Harnessing the prowess of artificial intelligence and computer vision, organizations are tackling intricate challenges, ensuring products align with the highest quality standards.

Explore some compelling applications of AI in Visual Quality Control across a spectrum of industries:

1. Manufacturing: In manufacturing, AI-driven Visual Quality Control swiftly identifies defects in metal parts, plastic components, and various manufactured goods, ensuring only top-tier items advance in the production pipeline.

2. Electronics and Semiconductor: AI plays a pivotal role in inspecting intricate circuit boards, connectors, and microchips in electronics manufacturing. This enhances the precision and reliability of electronic devices by adhering to stringent quality standards.

3. Automotive Quality Control: The automotive industry employs AI to inspect vehicles for defects in bodywork, paint finish, and critical components. This contributes to the production of safe, visually appealing, and high-performance automobiles.

4. Food and Beverage Production: In the food and beverage sector, AI-driven Visual Quality Control inspects packaging for defects, safeguarding product integrity and consumer safety by preventing issues such as improper seals or labeling errors.

5. Textile and Garment Industry: Textile manufacturers leverage AI to detect defects in fabrics and garments, ensuring that only flawless materials are used in clothing and textile production.

6. Pharmaceutical and Medical Device Quality Control: AI-powered Visual Quality Control plays a pivotal role in inspecting medical devices, implants, and pharmaceutical packaging. It contributes to the safety and efficacy of medical products by identifying even minor defects.

7. Aerospace Components Inspection: The aerospace industry benefits from AI-driven Visual Quality Control for inspecting intricate components such as engine parts and structural elements, ensuring safety and performance standards are upheld.

8. Consumer Electronics Manufacturing: In the consumer electronics sector, AI ensures that products like smartphones and appliances meet high aesthetic and functional standards through swift and accurate defect detection.

9. Healthcare and Medical Imaging: AI enhances quality control in medical imaging, identifying artifacts and abnormalities in X-rays, MRIs, and CT scans to ensure accurate diagnoses and treatment plans.

These diverse applications underscore the adaptability, accuracy, and efficiency of AI-driven Visual Quality Control. The technology empowers industries to maintain stringent quality standards, enhance customer satisfaction, and foster innovation in product development and manufacturing processes. As AI continues to evolve, its impact on visual quality control across industries is supposed to deepen further.

Effective Integration of AI Visual Inspection Systems into Business Operations

Integrating an AI visual inspection system into your business demands a methodical approach to seamlessly align the technology with existing quality control processes. This step-by-step guide provides a structured framework for a successful integration process:

Step 1: Define the Problem

Initiate the process by clearly understanding the problem statement and the inspection system’s goals. Concentrate on defects impacting product quality, safety, and reliability, and consider factors such as the manufacturing environment, real-time vs. deferred detection, system notifications, and the development approach.

Step 2: Gather and Prepare Data

Data forms the foundation of AI-powered systems. Collect and prepare datasets for training and validation, considering sources such as video records. Utilize IoT analytics for digitizing the supply chain, ensuring gathered data is well-organized and suitable for training.

Step 3: Develop Deep Learning Model

Choosing the Model: Select a suitable deep learning model based on factors like system complexity, budget, and time constraints.

Options for Model Development:

- Model Development Services: Utilize platforms like Google Cloud ML Engine or Amazon ML for pre-designed models based on heuristic rules.

- Pre-trained Models: Leverage pre-trained models designed for similar tasks, fine-tuning them to meet specific needs.

- Custom Model Development: Develop a custom deep learning model for precise and tailored results, using advanced computer vision algorithms.

Step 4: Train & Evaluate

Train the model using the prepared dataset, iterating to refine its capabilities. Evaluate its performance with validation datasets, measuring metrics such as precision, recall, and F1 score to gauge defect identification accuracy.

Step 5: Deploy & Improve

Deploy the AI visual inspection system, starting with a pilot deployment in a controlled setting. Integrate the model into the entire manufacturing system if it meets requirements, monitoring, and fine-tuning as necessary. Ensure continuous learning by regularly updating the model with new datasets and adapting to market trends.

By following these steps, your business can effectively integrate an AI-based visual inspection system for enhanced quality control. Tailor these guidelines to your specific needs, involving domain experts, data scientists, and software developers for successful integration into business operations.

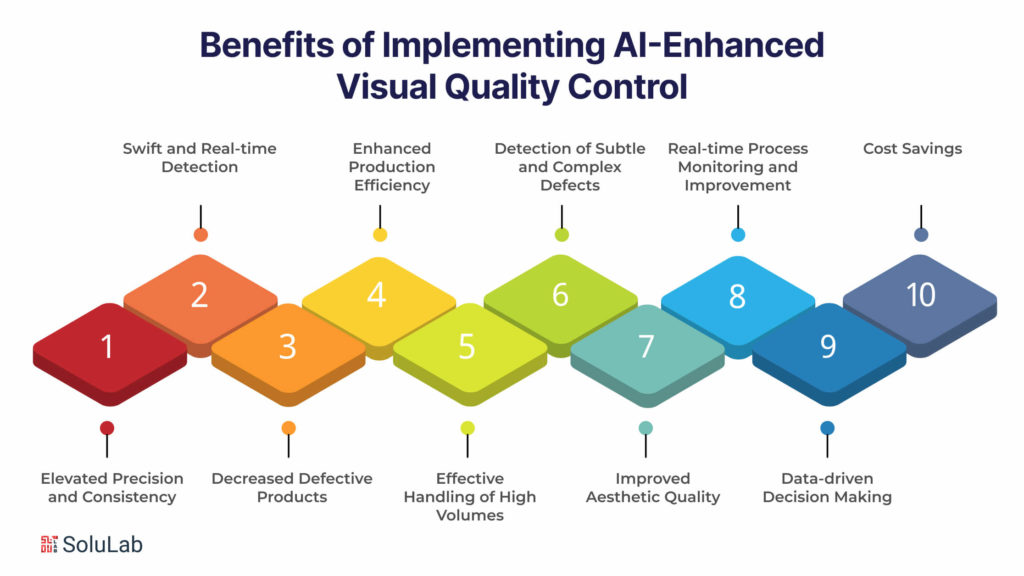

Benefits of Implementing AI-Enhanced Visual Quality Control

The infusion of AI into Visual Quality Control processes brings forth a multitude of advantages, significantly enhancing the precision, efficiency, and efficacy of quality assessment and defect detection. Leveraging Machine Learning (ML) and computer vision technologies, organizations witness remarkable improvements in their quality control practices. Here’s an in-depth exploration of the benefits derived from AI-driven visual quality control:

-

Elevated Precision and Consistency

AI-driven systems excel in consistent and accurate defect detection. Unlike human inspectors, AI algorithms remain unaffected by factors such as fatigue, mood swings, or distractions, ensuring a high level of assessment consistency. This leads to fewer false positives and negatives, guaranteeing the reliable detection of even subtle defects and reducing the likelihood of faulty products reaching consumers.

-

Swift and Real-time Detection

AI-powered Visual Quality Control systems operate in real-time, swiftly analyzing visual data as products traverse the production line. This rapid analysis facilitates instant defect detection, enabling immediate corrective actions. Addressing quality issues early in the process minimizes the spread of defects, preventing downstream problems and ensuring smoother production workflows.

-

Decreased Defective Products

A significant benefit of AI-driven quality control is the reduction in defective products reaching consumers. By identifying defects before products leave the production line, organizations can prevent costly recalls, mitigate customer complaints, and safeguard their reputation. This reduction in defects contributes to heightened customer satisfaction and loyalty.

-

Enhanced Production Efficiency

AI-powered systems operate at high speeds with minimal human intervention, accelerating the inspection process. This efficiency translates into improved production efficiency, allowing products to move through the production line more expeditiously without compromising on quality standards.

-

Effective Handling of High Volumes

AI-driven systems effectively handle large quantities of products at high speeds, avoiding bottlenecks that traditional manual inspections might encounter with high volumes. This scalability is particularly advantageous in industries with mass production requirements.

-

Detection of Subtle and Complex Defects

AI algorithms excel in identifying subtle defects that might challenge human inspectors. Moreover, they analyze complex visual data, including high-resolution images or multidimensional scans, to detect intricate defects. This advanced analysis ensures the identification of defects that could impact a product’s function or aesthetics.

-

Improved Aesthetic Quality

In industries where aesthetics play a pivotal role, AI-driven Visual Quality Control ensures that products meet high aesthetic standards. This encompasses assessing aspects like color consistency, surface finish, and overall appearance, aligning products with brand expectations.

-

Real-time Process Monitoring and Improvement

AI-driven systems offer real-time monitoring of production processes, providing insights into process performance by tracking defect rates and other metrics. This real-time data enables quick remedial measures and continual process improvement.

-

Data-driven Decision Making

AI-driven Visual Quality Control generates abundant data and insights from the inspection process, empowering enterprises to make informed decisions about process optimization, product design enhancements, and supplier quality management. Decisions based on data lead to improved effectiveness and efficiency in quality control procedures.

-

Cost Savings

While the initial implementation of AI-driven systems involves an investment in technology and training, the long-term benefits result in substantial cost savings. Reduced imperfections, fewer recalls, and enhanced operational efficiency all contribute to higher ROI over time. Additionally, these systems minimize the need for extensive manual inspections, reducing labor costs.

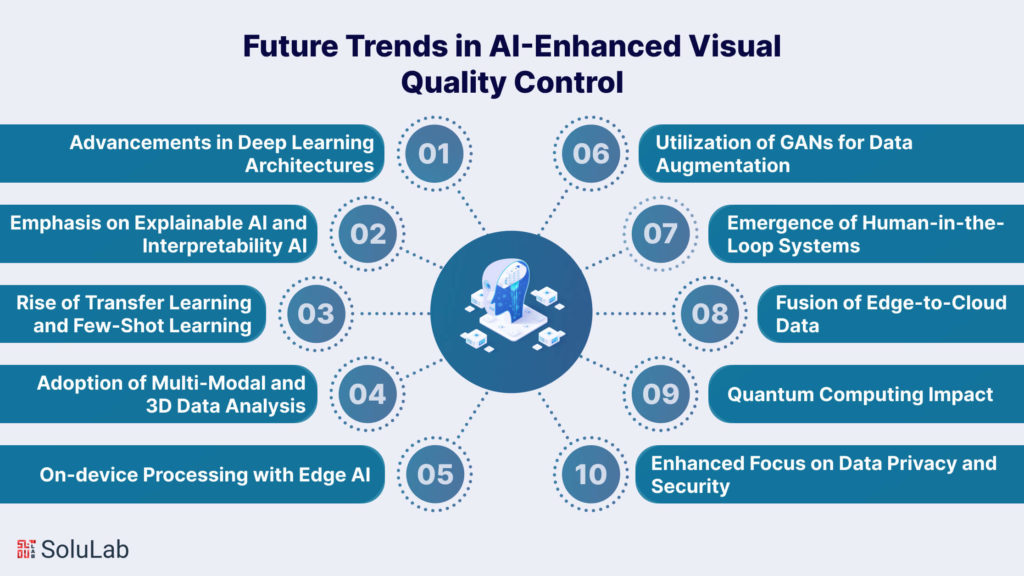

Future Trends in AI-Enhanced Visual Quality Control

The landscape of AI in Visual Quality Control is swiftly evolving, propelled by strides in artificial intelligence, computer vision, and manufacturing technologies. As industries embrace AI-powered solutions, several forthcoming trends are set to redefine the future of Visual Quality Control. Let’s delve into a comprehensive exploration of these impending trends:

-

Advancements in Deep Learning Architectures

The future heralds the exploration of advanced deep learning architectures beyond Convolutional Neural Networks (CNNs). Techniques such as capsule networks and transformers will play a pivotal role in handling more intricate visual data, fostering a nuanced understanding of context, and elevating accuracy in defect detection.

-

Emphasis on Explainable AI and Interpretability

The demand for transparency and interpretability in AI decisions is gaining momentum. In Visual Quality Control, efforts are underway to develop models and techniques that provide interpretable explanations for AI-driven assessments. This focus on explainability enhances the transparency and trustworthiness of the decision-making process.

-

Rise of Transfer Learning and Few-Shot Learning

Transfer learning and few-shot learning are becoming indispensable in AI for quality control. Pretrained models can be fine-tuned with smaller, industry-specific datasets, enabling AI systems to swiftly adapt to new quality control tasks with limited training data. This approach enhances accessibility and applicability across diverse industries.

-

Adoption of Multi-Modal and 3D Data Analysis

The integration of multi-modal data, combining visual, textual, or sensor data, and the analysis of three-dimensional (3D) data are poised to become more prevalent. AI systems will leverage these capabilities to make more informed quality assessments, particularly in industries like aerospace, automotive, and healthcare, where 3D data analysis can pinpoint defects in intricate components and structures.

-

On-device Processing with Edge AI

Edge AI, involving local computations on devices rather than in the cloud, is gaining prominence. On-device processing improves privacy and minimizes latency, making it useful for real-time quality control. Equipping cameras, sensors, and devices on the production line with AI capabilities ensures immediate defect detection without relying on cloud resources.

-

Utilization of Generative Adversarial Networks (GANs) for Data Augmentation

GANs, a distinctive Generative AI models, will be increasingly employed for data augmentation. In quality control, GANs generate synthetic data closely resembling real data, especially for rare or challenging-to-capture defects. This augmented dataset improves the generalization and performance of AI models, particularly in scenarios with limited annotated data.

-

Emergence of Human-in-the-Loop Systems

AI-driven quality control will witness a surge in human-in-the-loop systems, where human inspectors collaborate with AI systems, validating and verifying assessments. This collaborative approach ensures that the AI system learns from human feedback, refining its performance and adapting to new defect types.

-

Fusion of Edge-to-Cloud Data

The amalgamation of edge-device data with cloud-based analysis will provide a holistic view of quality control processes. Preliminary inspections conducted by edge devices will be complemented by cloud-based systems, offering a comprehensive analysis of data from multiple sources to identify overarching quality trends and anomalies.

-

Quantum Computing Impact

Advancements in quantum computing may have profound applications in solving complex optimization problems related to quality control. This includes optimizing inspection algorithms, analyzing vast datasets, and simulating intricate manufacturing processes, ultimately leading to more efficient and effective quality control strategies.

-

Enhanced Focus on Data Privacy and Security

As AI systems handle sensitive visual data, paramount importance will be placed on data privacy and security. Technologies like federated learning, which trains models across distributed devices while keeping data locally, will gain traction to safeguard sensitive visual data.

The future of AI in Visual Quality Control promises exciting possibilities. With advancements spanning interpretability, multi-modal analysis, and beyond, these trends collectively signal a new era of quality assurance. This evolution will not only enhance products and increase efficiency but also drive innovation across industries.

Conclusion

In conclusion, the future of Visual Quality Control is undeniably intertwined with the relentless evolution of artificial intelligence. The anticipated trends in advanced deep learning architectures, explainable AI, transfer learning, multi-modal data analysis, and more are poised to reshape the landscape of quality assurance across industries. As businesses increasingly leverage AI-driven systems, the synergy of cutting-edge technologies promises not only heightened accuracy and efficiency but also a transformative impact on product quality and manufacturing processes.

As we navigate the path toward this AI-driven future, it’s crucial for industries to stay agile, adapting to emerging trends and harnessing the power of innovation. The convergence of human expertise with AI capabilities, the fusion of edge-to-cloud data, and the potential impact of quantum computing underscore the collaborative and dynamic nature of this transformation. The journey ahead holds exciting possibilities, where each trend represents a building block in the construction of a robust and adaptable Visual Quality Control ecosystem.

For those seeking to embark on this transformative journey, SoluLab stands as a pioneering partner in the realm of AI in Visual Quality Control. With a proven track record in developing great solutions, SoluLab leverages its expertise in AI, computer vision, and industry-specific insights to tailor solutions that meet the unique challenges of Visual Quality Control. To take the first step toward revolutionizing your quality control processes, explore how SoluLab’s comprehensive AI Development solutions can elevate your organization’s standards and efficiencies. Embrace the future of Visual Quality Control with SoluLab – where innovation meets excellence.

FAQs

1. How does AI improve accuracy in Visual Quality Control?

AI enhances accuracy by leveraging advanced deep learning architectures such as Convolutional Neural Networks (CNNs). These models excel at detecting subtle defects, reducing false positives and negatives. Additionally, AI-driven systems eliminate human factors like fatigue and distractions, ensuring consistent and precise defect detection in real time.

2. Why is explainable AI crucial in Visual Quality Control?

Explainable AI is essential to provide transparency in decision-making processes. In Visual Quality Control, understanding why an AI system classifies a defect or accepts a product is vital for trust and accountability. Efforts are underway to develop models that offer interpretable explanations, ensuring a clear understanding of the basis for AI-driven assessments.

3. How does transfer learning benefit AI in quality control?

Transfer learning enables AI models to leverage pre-existing knowledge from pre-trained models. In Visual Quality Control, this means that models can be fine-tuned with smaller, industry-specific datasets, making them adaptable to new tasks with limited training data. This approach enhances the accessibility and applicability of AI across diverse industries.

4. What role does edge AI play in real-time quality control?

Edge AI, involving local computations on devices rather than in the cloud, is crucial for real-time quality control. By processing data locally, edge AI reduces latency, ensuring immediate defect detection. Cameras, sensors, and devices equipped with AI capabilities on the production line can swiftly identify defects without relying on cloud resources.

5. How does SoluLab contribute to AI in Visual Quality Control?

SoluLab is a leading expert in AI solutions for Visual Quality Control. Leveraging expertise in AI, computer vision, and industry-specific insights, our company tailors solutions to address the unique challenges of quality control. By providing comprehensive AI consulting services, SoluLab empowers organizations to revolutionize their quality control processes and elevate standards of efficiency and excellence.