The global AI in supply chain market is projected to reach $41.23 billion by 2030, growing at a CAGR of 38.8% from 2023 to 2030. Managing an online retail firm necessitates real-time visibility of items from warehouse to consumer doorstep. This entails coordinating many communications between suppliers, warehouses, and delivery providers. However, manual methods frequently result in little visibility, regular disruptions, and inadequate data, all of which can put a strain on operations. Such inefficiencies are prevalent, and up to 60% of organizations suffer considerable revenue losses as a result.

With the introduction of AI agents, supply chain management, and logistics are revolutionizing in today’s world. Considering the multitude of features these intelligent systems provide, you may improve and optimize every part of your supply chain. Artificial intelligence (AI) agents drastically lower mistakes, speed up reaction times, and increase overall efficiency in a variety of tasks, from automating warehouse operations and forecasting demand to tracking inventory and routing.

In this blog, we will look into the role of AI agents in supply chain and logistics with various types of agents in AI, as well as the essential parts of these complex systems. We’ll explore their wide range of uses and the important advantages they provide to companies. We will also go over recommended practices and the process of creating AI agents for logistics. Lastly, to give you a complete picture of how artificial intelligence is affecting supply chain management and logistics, we will be looking at the upcoming trends that will direct this sector.

AI agents are autonomous software systems that have the ability to sense their surroundings, decide what to do, and act to accomplish predetermined objectives. They represent a major breakthrough in artificial intelligence, combining AI capability with human-like decision-making and interaction abilities. Simple rule-based systems and sophisticated machine-learning models are two examples of AI agents. They are meant to function on their own, free from continual human direction or oversight.

These intelligent agents are capable of managing a wide range of jobs, including creative projects, process optimization, customer service, and making strategic choices. Artificial intelligence (AI) agents may boost productivity, enhance customer experiences, and propel corporate development and competitiveness in the digital age by reducing repetitive operations and utilizing data-driven insights.

As per the recent studies, AI-enabled supply chain management can reduce logistics costs by 15%, inventory levels by 20%, and service levels by 40%. AI agents are transforming how organizations engage with both digital and physical surroundings. Here are the main functions that define these intelligent agents:

Read Also: AI Agents for Procurement

There are many different kinds of AI agents, and each has its own set of features and uses. The several types of agent in AI are as follows:

1. Simple Reflex Agents: These agents respond immediately to their immediate sensory input without building an internal representation of their surroundings. Instead, they operate according to condition-action principles. They work well in settings where the only thing influencing behavior is one’s current viewpoint. However, since they are unable to anticipate outcomes or make plans based on prior experiences, they suffer in complicated or unstructured contexts.

2. Model-based Reflex Agents: These agents keep a mental image of their surroundings. They can deal with partially visible surroundings thanks to this representation since it enables them to draw conclusions about missing data from their past knowledge and current impressions. They are more adaptive to shifting or unpredictable situations because they make decisions about what to do based on both their internal model of the world and their present observations.

3. Goal-based Agents: These agents evaluate the potential outcomes of their choices and base their choices on the likelihood that their goals will be met. They are suited for difficult decision-making activities because of their capacity to organize and select courses of action that will provide desired results.

4. Utility-based Agents: These agents use a utility function to assess the attractiveness of several potential outcomes. This function gives several states numerical values that represent their relative worth or preference. The agent attempts to maximize this utility function in order to get the best possible result in any given circumstance. This strategy is especially useful in situations when there are several viable courses of action or results because it enables the agent to decide on a course of action based on a defined value.

5. Learning Agents: Because of their expertise, these agents gradually become more effective, which is especially useful in dynamic contexts. They modify and develop their tactics, always honing their comprehension to maximize results.

6. Multi-Agent Systems (MAS): In MAS, a number of agents collaborate and work toward shared or separate objectives. MAS is used for complicated operations that need coordination, such as supply chain management, where multiple agents stand in for different supply chain components.

7. Hierarchical Agents: These agents are ones in which higher-level agents oversee and manage lower-level ones. Every level in the hierarchy has distinct functions and duties that support large-scale systems where actions must be managed at many levels and contribute to the ultimate objective.

AI agents for logistics and supply chain are advanced software systems developed to streamline and optimize numerous processes in these businesses. These intelligent agents utilize machine learning, data analytics, and natural language processing to complete activities that formerly required human interaction. AI agents can use massive volumes of data to estimate demand, handle inventory, improve delivery routes, and boost decision-making processes. They considerably enhance productivity, cut costs, and boost accuracy in logistics and supply chain management, helping firms to react quickly to changing market conditions and client needs.

The following are the key capabilities of AI agents in logistics and supply chain.

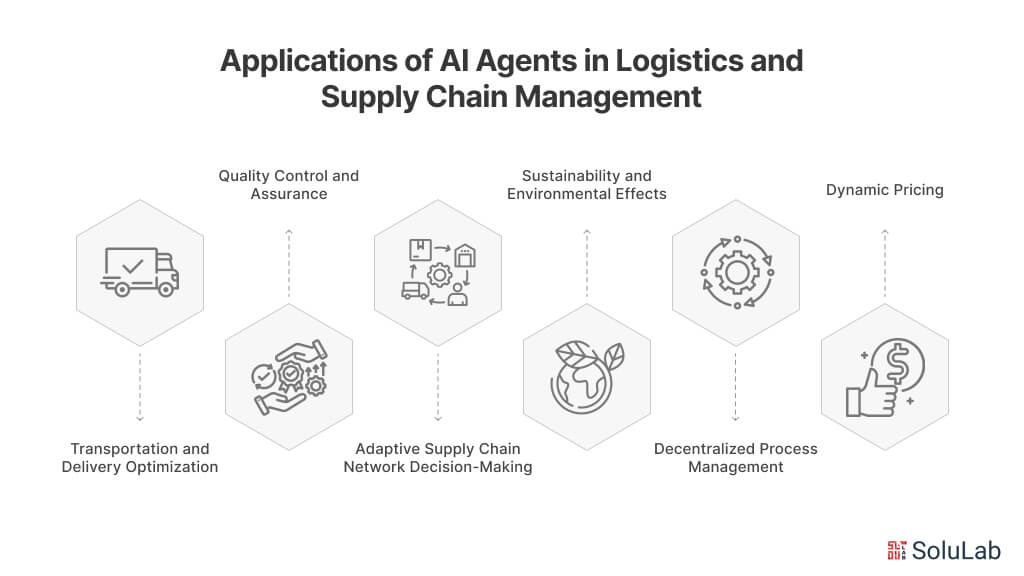

AI agents play an important role in revolutionizing logistics and supply chain management via a variety of applications. Here are some prominent areas where supply chain AI is having a substantial impact:

Large Language Model (LLM) agents improve transportation and delivery optimization by assessing real-time data such as traffic patterns, weather conditions, and delivery schedules to suggest the most effective routes. These AI agents help with fleet management by assessing vehicle performance data, forecasting maintenance requirements, and modeling the incorporation of self-driving trucks into current delivery operations. LLM agents use these skills to reduce downtime, lower labor costs, and increase the overall effectiveness in transportation and delivery operations. In some cases, businesses may also collaborate with a fleet management software development company to create tailored systems that integrate AI capabilities into their existing vehicle tracking and dispatch workflows.

AI agents may detect possible root causes of product defects, evaluate trends in defects, and suggest preventive actions to enhance quality control along the supply chain. These agents are trained on data from automated inspections using computer vision. In-depth reports that summarize inspection findings and provide remedial measures to enhance manufacturing procedures can also be produced by them. By analyzing real-time data from several supply chain stages, data analysis may assist spot trends and anomalies that point to problems with production, shipping, and warehousing quality. By enabling ongoing process improvement, this data-driven strategy upholds high standards of quality across the whole supply chain.

Through data analysis from logistical operations, AI agents may help businesses optimize resource utilization, decrease waste, and cut down on energy use. Additionally, they may track the carbon impact of supply chain operations and spot areas for development. Moreover, by evaluating supplier practices data, locating ethical and sustainable material suppliers, and suggesting substitutes, LLMs can assist sustainable sourcing.

When conditions change, autonomous AI agents are excellent at making adaptive decisions and dynamically modifying supply chains. They discover new suppliers, suggest other routes, or modify inventory allocations in response to unforeseen occurrences like supplier outages or delays in transit. Because of its agility, the supply chain as a whole is less vulnerable to interruptions and threats. AI agents make sure everything runs well by keeping an eye on consignments, inventory levels, and outside variables all the time.

By allowing effective data collection and analysis, delivering real-time event alerts, and fostering cooperative decision-making for suppliers, manufacturers, distributors, and retailers, AI agents may assist decentralized process management throughout supply chain activities. By exchanging real-time data on inventory levels, demand trends, production capacity, and transportation schedules, AI agents for supply chain improve teamwork. Throughout the supply chain, this decentralized design enhances decision-making, information flow, and resource use.

AI agents are essential to dynamic pricing strategies because they continually monitor inventory levels, rival prices, and market demand in real time. These agents are capable of analyzing enormous volumes of data to find patterns and trends that help determine the best prices. Businesses can react quickly to changes in the market thanks to this dynamic pricing modification, which keeps them competitive and maximizes income. For example, AI agents might raise pricing in times of high demand to take advantage of consumers’ desire to pay more, or they can lower prices in times of low demand to encourage sales and prevent surplus inventory. In addition to increasing profitability, this real-time price flexibility helps keep supply and demand in balance, enhancing overall market efficiency.

Artificial Intelligence (AI) agents are revolutionizing the supply chain and logistics industry. Their ability to analyze data, optimize processes, and make intelligent decisions brings numerous benefits. Here are some key benefits of agents in AI in logistics and supply chain operations:

AI agents in logistics analyze real-time traffic data, weather conditions, and delivery schedules to determine the most efficient routes. This reduces fuel consumption, delivery times, and operational costs while improving customer satisfaction.

AI-driven robots and agents can handle tasks such as picking, packing, and sorting in warehouses. This automation increases efficiency, reduces errors, and lowers labor costs, leading to a more streamlined operation.

AI agents help in evaluating supplier performance based on criteria such as delivery times, quality, and cost. This facilitates better supplier selection, improved negotiations, and stronger relationships.

By analyzing various risk factors, AI agents can predict potential disruptions in the supply chain, such as geopolitical events, natural disasters, or supplier failures. This proactive approach enables companies to develop contingency plans and minimize impact.

AI agents enhance security by monitoring transactions and supply chain activities for suspicious patterns and potential fraud. They can quickly identify and flag anomalies, reducing the risk of fraud and ensuring the integrity of operations.

AI agents facilitate better communication and collaboration across the supply chain by integrating data from various sources and providing a unified view. This helps in synchronizing activities and improving coordination among partners and stakeholders.

AI solutions are scalable, meaning they can grow with the business. As supply chain operations expand, AI agents can handle increased data volumes and complexity, ensuring continued efficiency and performance.

AI agents assist in workforce planning by predicting labor needs based on demand forecasts and operational requirements. This helps in optimizing labor allocation and improving workforce productivity.

By leveraging AI-driven insights, companies can identify new market opportunities and expansion strategies. This includes understanding regional demands, consumer behavior, and competitive landscapes to make informed decisions about entering new markets.

In humanitarian efforts, AI agents can optimize logistics for faster and more efficient delivery of aid. They can predict needs based on disaster patterns, ensuring timely and effective responses in critical situations.

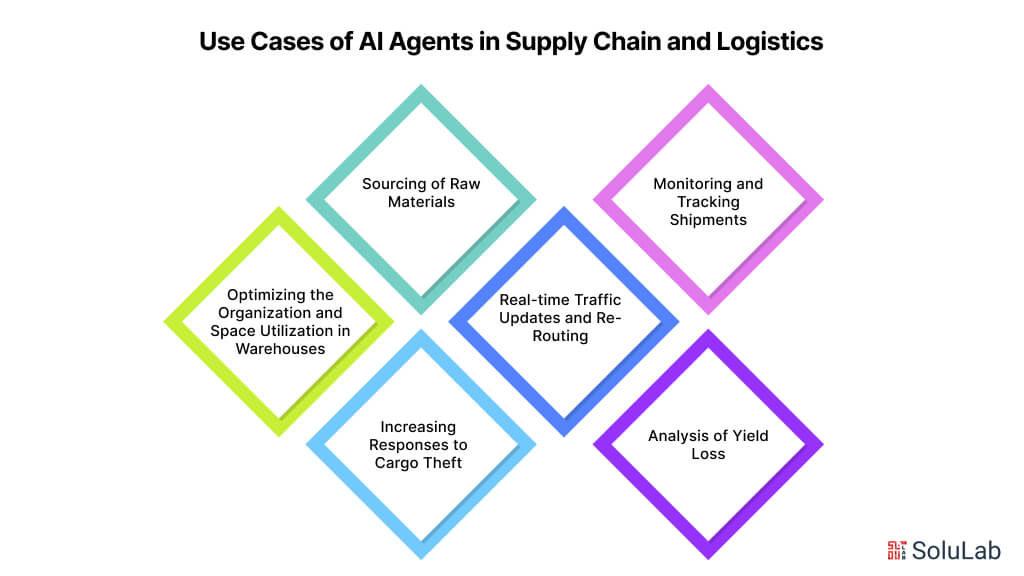

Artificial intelligence algorithms are capable of evaluating variables including supplier dependability, price swings, quality requirements, and geographic closeness in order to choose the best raw material suppliers. Artificial Intelligence (AI) in the supply chain helps producers detect any interruptions, negotiate better prices, and guarantee a steady and economical supply of raw materials by continually monitoring market circumstances and supplier performance. This data-driven strategy cuts waste lowers production downtime, and improves the effectiveness of obtaining raw materials.

By enhancing supply chain security and incident reaction times, artificial intelligence greatly improves efforts to avoid cargo theft. Shippers may proactively manage and minimize risks by utilizing AI in this way. They may also respond quickly to suspected thefts, helping to prevent cargo losses and safeguard the supply chain. A great illustration of this use is Overhaul’s RiskGPT. Over time, AI-driven solutions like RiskGPT have become more and more adept at foiling theft attempts as a result of their constant learning and adaptation from fresh data. RiskGPT can scan and evaluate large volumes of data, including past theft trends, current location data, and real-time information from devices like GPS trackers when there is a possible danger of theft. Shippers may receive prompt, contextually appropriate advice on how to react to particular occurrences from it.

One of the biggest challenges facing logistics organizations is traffic congestion. On the other hand, AI allows businesses to continually monitor real-time traffic conditions. Artificial intelligence systems intervene to reroute delivery in response to delays, guaranteeing on-time arrivals. AI is especially useful since it can account for weather, accidents, and road closures. AI can give logistics businesses precise, up-to-date information by taking into account these dynamic elements. This will enable them to make quick choices and improve their delivery routes, which will eventually reduce delays and increase efficiency.

The layout of a warehouse and the efficient use of available space improve operational effectiveness. Logistics firms can examine data about product demand, inventory levels, and other factors to optimize warehouse architecture and increase space usage by utilizing AI-driven optimization. AI is capable of optimizing warehouse space by recommending the best way to use storage rooms. To make room for things with different sizes or storage needs, shelves, racks, or bins may need to be rearranged. By carefully planning every optimization, order picking and packing times are shortened, storage space is increased, and overall operational efficiency is raised.

Effective cargo tracking and monitoring are essential to guaranteeing on-time and undamaged delivery. AI in logistics and supply chain enables businesses to track shipments in real-time and get warnings quickly when there are delays or issues. Furthermore, AI systems are skilled at analyzing shipping data, including travel durations and associated variables, to anticipate any issues and take proactive steps to address them. In order to optimize delivery routes and schedules and assist in decreasing delivery times, enhance efficiency, and boost customer happiness, it may evaluate data on delivery locations, traffic patterns, and other aspects. This logistic agent strategy improves dependability and client pleasure by guaranteeing shipments arrive on time and in ideal form.

Beyond just improving previously effective procedures, AI and logistics also entail evaluating underperforming operations in order to derive insightful knowledge. For example, via the analysis of production data and the identification of underlying variables impacting yield rates and product quality, AI-driven solutions allow businesses to maximize yields. These solutions make it easier to identify problems with the way products are made or how operations are run, which helps to streamline operations and cut costs.

Artificial Intelligence (AI) has a bright future ahead of it in supply chain and logistics, and major industry changes are anticipated. The following are some developments and forecasts about the use of AI in supply chain and logistics going forward:

In conclusion, the integration of AI agents in supply chain and logistics is revolutionizing the industry by enhancing efficiency, accuracy, and scalability. Supply chain AI is transforming traditional processes, enabling businesses to forecast demand, optimize routes, and manage inventory with unprecedented precision. The adoption of artificial intelligence in logistics is driving a new era of innovation, where data-driven decision-making leads to significant cost savings and improved customer satisfaction. As companies continue to embrace these technologies, the future of supply chain management looks promising and full of potential.

However, the journey to fully utilize artificial intelligence in logistics is not without its challenges. Issues such as data quality, integration with existing systems, and the need for skilled personnel can hinder progress. This is where SoluLab, as a leading AI agent development company, can make a difference. Our expertise in developing customized AI solutions ensures that these obstacles are effectively addressed, allowing businesses to harness the full power of supply chain AI. From improving data accuracy to seamless system integration, SoluLab provides end-to-end support to optimize your logistics operations. Ready to transform your supply chain with artificial intelligence? Contact us today to learn how we can help.

AI agents are used in supply chain and logistics to enhance forecasting accuracy, optimize routing, manage inventory, and improve overall efficiency. They analyze vast amounts of data to provide insights that drive better decision-making, leading to cost savings and improved customer satisfaction.

Implementing AI in supply chain management offers several benefits, including increased efficiency, reduced operational costs, improved demand forecasting, optimized inventory levels, enhanced customer service, and better risk management. AI-driven solutions enable businesses to stay competitive and responsive to market changes.

Businesses may face challenges such as poor data quality, difficulty integrating AI with existing systems, high implementation costs, and a lack of skilled personnel to manage AI technologies. These challenges can slow down the adoption of AI and limit its potential benefits.

SoluLab can help overcome these challenges by providing customized AI solutions tailored to your specific needs. Our expertise ensures high data accuracy, seamless system integration, and comprehensive support throughout the implementation process. We also offer training and support to help your team effectively manage AI technologies.

The future of AI in supply chain and logistics is bright, with continuous advancements leading to more sophisticated and efficient operations. AI will play a crucial role in enhancing predictive analytics, automating routine tasks, and enabling more responsive and agile supply chains. As technology evolves, businesses that embrace AI will gain a significant competitive edge.